Towards Zero Gas Flaring: Digital Optimization of Industrial Gas Networks

Introduction

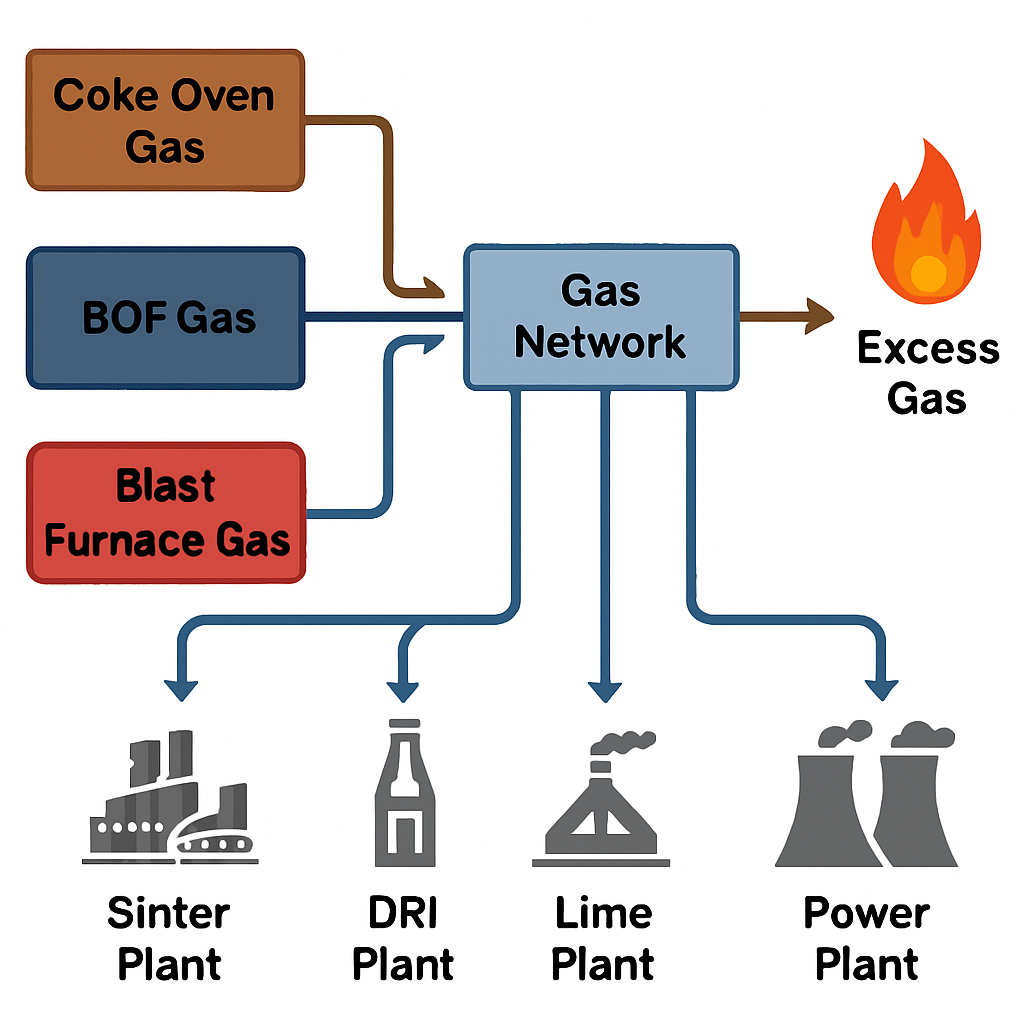

In integrated steel plants, large quantities of process gases are generated as by-products of high-temperature metallurgical reactions. These gases-Coke Oven Gas (COG), Basic Oxygen Furnace Gas (BOFG), and Blast Furnace Gas (BFG)-possess significant calorific value and are valuable sources of secondary energy.

However, managing their fluctuating generation rates and diverse energy contents is a complex challenge. When not properly optimized, excess gas leads to flaring-a process that not only wastes valuable energy but also contributes to greenhouse gas emissions.

With the growing emphasis on sustainability and efficiency, digitalization and optimization of gas networks have become essential. By leveraging AI/ML-based models, plants can balance gas supply and demand in real time, stabilize pressure and calorific values, and ultimately move towards a zero-flaring objective.

Understanding Gas Generation Units in Steel Plants

- Coke Oven Gas (COG)

Coke Oven Gas is a by-product of the coke-making process, where coal is carbonized in the absence of air. It is rich in hydrogen, methane, and carbon monoxide, giving it a high calorific value. COG is typically used in reheating furnaces, lime kilns, and power plants due to its clean-burning characteristics. However, its generation depends on the coke oven’s operating cycles and can fluctuate significantly. - Basic Oxygen Furnace Gas (BOFG)

The Basic Oxygen Furnace (BOF) process-used to convert hot metal into steel-produces gas that contains carbon monoxide, carbon dioxide, and small amounts of hydrogen. The gas composition varies with the steelmaking stages, making real-time monitoring and recovery essential. Once cleaned and cooled, BOF gas can be reused as a fuel in sinter plants, reheating furnaces, or power generation units. - Blast Furnace Gas (BFG)

Blast Furnace Gas, generated during ironmaking, has the lowest calorific value among the three but is produced in the largest quantity. BFG is a crucial fuel source for stoves, sinter plants, and pellet plants. Its pressure and flow variations, however, pose challenges to consistent utilization.

Fig: Generation and consumption trends for BFG, COG, and BOFG

Consumption Units of Process Gas

Once generated, these gases are distributed across various consumers within the plant complex:

- Sinter Plant & Pellet Plant: Used for heating and maintaining bed temperature during ore agglomeration.

- Direct Reduced Iron (DRI) Plant: Uses Coke Oven Gas (COG) or mixed process gases not only as a fuel source but also as a reducing agent. The hydrogen (H₂) and carbon monoxide (CO) present in these gases react with iron oxides in the reactor, reducing them to metallic iron. Thus, the gas plays a dual role - providing both the necessary thermal energy and the chemical environment for reduction.

- Lime Plant: Consumes COG and BFG to produce quicklime, essential for steel refining.

- Reheating Furnaces & Tundish Heaters: Use COG for consistent flame temperature and quality heating.

- Power Plants: Convert excess process gas into electricity, ensuring overall energy efficiency.

An ideal network balances gas supply and consumption, ensuring minimal gas is sent to flaring stacks. However, frequent load changes, unit shutdowns, and inconsistent gas quality often disrupt this balance.

Challenges in Conventional Gas Network Operations

- Inconsistent Gas Generation: Gas production rates depend heavily on the operating condition of each metallurgical unit. Sudden production drops or unplanned stoppages can disturb the network equilibrium.

- Variable Calorific Value and Pressure: Each gas has unique calorific characteristics. Mixing them without proper control can lead to unstable burner performance or inefficient combustion.

- Manual Decision-Making: Operators often rely on standard operating procedures and experience-based rules, making real-time optimization difficult under dynamic plant conditions.

- Unpredictable Gas Demand: Consumer units such as reheating furnaces or sinter plants frequently change their load requirements, making it challenging to match supply and demand in real time.

Digital Approach for Gas Network Optimisation

- Data-Driven Model Development

To manage a complex gas network, data becomes the foundation. Key datasets include:

- Real-time gas generation and consumption rates.

- Pressure and calorific value (CV) data at mixing stations.

- Historical breakdowns and process stoppage logs.

- Production data of each gas-producing and consuming unit.

AI/ML models use this data to:

- Forecast gas generation based on operating parameters of COG, BOF, and BF units.

- Predict gas demand based on the production schedules of consumption units.

- Optimise gas allocation to maintain stable pressure, reduce losses, and minimise flaring.

- Model Implementation and Integration

Once trained, the model is integrated with plant control systems (either on-premises or via a secure cloud interface). It continuously monitors real-time parameters and provides actionable insights, such as:

- Optimal blending ratios of different gases to achieve target calorific values.

- Real-time alerts for surplus gas that should be diverted to power generation rather than flaring.

- Recommended valve or compressor adjustments to stabilise pressure.

This closed-loop decision support enables operators to make data-backed decisions instead of relying solely on manual adjustments.

- Optimization Algorithms

Advanced optimisation algorithms such as Genetic Algorithms (GA), Benders Decomposition, Deep Q-Networks (DQN), Multi-Agent Reinforcement Learning (MARL) and Particle Swarm Optimisation (PSO) are used to dynamically adjust the gas distribution strategy. These algorithms evaluate multiple combinations of gas allocation and consumption patterns to minimise losses while maintaining safety and operational limits.

Benefits of Gas Network Digitalisation

- Energy Efficiency: Maximising internal gas utilisation reduces dependency on external fuels.

- Reduced Flaring: By forecasting gas surpluses and rerouting them effectively, plants can approach the zero-flare target.

- Operational Stability: Constant pressure and CV at mixing stations ensure smoother combustion and lower equipment stress.

- Sustainability and Compliance: Lower emissions and efficient resource use support environmental goals and regulatory standards.

- Economic Gains: Reduced energy losses translate directly into cost savings.

Conclusion

Optimizing the gas network in an integrated steel plant is more than an energy-saving initiative; it’s a step towards sustainable manufacturing. By embracing digital solutions powered by machine learning and optimization algorithms, plants can intelligently balance gas supply and demand, reduce flaring, and enhance overall efficiency.

The path to zero flaring lies in predictive analytics, real-time monitoring, and smart control integration, transforming what was once a manual, experience-based operation into a truly intelligent system.

References

- International Energy Agency (IEA). (2020). Iron and Steel Technology Roadmap. Paris: IEA.

- World Steel Association. (2024–2025). World Steel in Figures and Energy Use / Sustainability Fact Sheets. Brussels: World Steel Association.

- Kumar, D., & Chakraborty, D. (2025). Digital Transformation & Energy Efficiency to Enhance Sustainability in Indian Iron and Steel Industry: An Empirical Study of Integrated Steel Plants (Steel Authority of India Limited). Department of Humanities and Social Sciences, National Institute of Technology Durgapur, India.

AI PlantOps

AI PlantOps was built to bridge this gap. It fuses domain intelligence, machine learning, symbolic reasoning, and physics-based validation into one interconnected operating system. The result: a new paradigm of AI PlantOps — where every section, cluster, and workflow is digitally traceable, intelligently optimized, and seamlessly connected.

Book a Demo →Dx. Consulting Services

Our strength lies in the fusion of deep consulting experience, process domain expertise, and digital execution excellence. This rare combination enables us to go beyond traditional digital transformation.

Book a Meeting →Agentic AI Services

Knowledge Graph as a Service (KGaaS) is a scalable, agent-driven platform that transforms siloed, unstructured, and structured industrial data into a semantically connected, intelligent knowledge network. Built on industry standards and ontologies, the platform enables next-gen applications in root cause analysis, process optimization, SOP automation, and decision augmentation.

Book a Meeting →FAQs

Q1. What are the main sources of process gas in a steel plant?

CE is the ratio of actual aluminium produced to the theoretical yield, indicating electrical-to-metal conversion efficiency.

What is the difference between anode spikes and anode effects?

Anode spikes are short local disturbances from solid deposits, while anode effects are cell-wide voltage rises due to low alumina.

How does FTP alumina affect AlF₃ dosing?

FTP alumina contains variable HF that changes bath fluoride balance, altering the required AlF₃ addition rate.

How can AI help when data is mostly manual?

AI predicts process behaviour and anomalies using historical manual data, providing continuous virtual insights.

Related Blogs

Digital Transformation of Aluminium Pot rooms: AI-Driven Strategies for Pot Health and Efficiency

Supercharging Lime Kiln Operations with Digital Twin and AI Innovation