Supercharging Lime Kiln Operations with Digital Twin and AI Innovation

Introduction

As industrial sectors continue to embrace Industry 4.0, digital transformation becomes a strategic imperative. Among the most impactful innovations in this evolution is the digital twin, a virtual replica of a physical system that mirrors and simulates real-time performance. For complex operations such as lime kilns in integrated steel plants, digital twins offer powerful tools for optimization, cost reduction, and improved process reliability. This article explores the role of digital twins in modern lime kilns, their benefits, core applications, and key challenges.

Lime, a crucial flux in steelmaking, is indispensable for refining processes. Modern steel plants deploy twin-shaft Parallel Flow Regenerative (PFR) kilns capable of processing 300 to 600 tons per day. These kilns operate as packed bed reactors with cyclic heating and reheating phases, making real-time monitoring and quality control difficult. A digital twin can bridge this gap by integrating sensor data and advanced analytics to provide actionable insights.

Key Benefits of Digital Twin Technology in Lime Kilns

- Predictive Maintenance

Lime kilns are highly automated but remain operational black boxes due to the complexity of their packed-bed design. Predictive maintenance using digital twins can pre-empt mechanical failures by continuously analysing machine and process data. This leads to reduced unplanned downtimes, lower maintenance costs, and extended equipment life.

- Enhanced Quality Control

Two main quality indicators in lime production are Loss on Ignition (LOI) and reactivity. Traditional quality assurance relies heavily on lab testing, which is delayed and reactive. A digital twin can predict these metrics using process parameters like fuel flow, channel temperature, and cycle times, enabling operators to fine-tune conditions in real time and maintain consistent product quality.

- Safety and Environmental Impact

Optimized kiln operation not only saves fuel but also minimizes CO2 emissions. Furthermore, simulation-based fault prediction enhances workplace safety by allowing proactive risk mitigation. Thus, digital twins support both sustainability and occupational safety.

Core Applications of Digital Twin in Lime Kiln Operations

- Soft Sensor for Lime Quality Prediction

Limestone remains in a kiln for around 24 hours. The extended residence time and packed bed structure hinder real-time quality measurement. A machine learning (ML)-based soft sensor model can estimate LOI using inputs such as:

- Combustion air and fuel rate

- Waste gas temperature

- Cooling air flow

- Limestone size distribution and chemistry

- Average kiln cycle time

This model reduces dependence on laboratory testing and helps maintain steady quality, ultimately lowering process variation and cost.

Figure 1: Actual vs Predicted LOI

- Fuel Optimization through Channel Temperature Control

Kiln performance hinges on channel temperature (typically 850–950°C), a proxy for calcination efficiency. A digital twin incorporating ML algorithms can regulate fuel flow dynamically to stabilize this temperature, thereby:

- Enhancing lime quality (target LOI ~5%)

- Reducing fuel consumption

- Improving process efficiency

Figure 2: Tentative fuel saving with model

- Abnormality Detection in Kiln Reactor

Packed bed reactors like PFR kilns are prone to anomalies such as channelling and clustering, which lead to uneven heating and product inconsistencies. Using historical and real-time data, a digital twin model can flag deviations in flow or temperature profiles that may indicate such issues. Early detection allows corrective actions before quality or safety is compromised.

Figure 3: Temperature Profile for kiln zones

- Pneumatic Conveying System Monitoring

Due to its brittle nature, lime generates fine dust during handling. To prevent moisture absorption and maintain quality, pneumatic conveying with dry nitrogen is used. However, conveying lines are susceptible to blockages from pressure drops or lump formation. An ML-based alarm system, integrated with pressure sensors, can predict potential choking, ensure uninterrupted material flow, and minimize downtime.

- Minimizing Limestone Undersize Generation

Undersized generation in limestone handling results in raw material loss, lower circuit yield, and increased wear and maintenance. A significant contributor is the dumping of limestone into empty storage bins, which causes particle breakage due to high impact forces. This effect is exacerbated as the rake progresses, reducing the average particle size.

An AI/ML-based system can dynamically recommend optimal bins for limestone dumping. By analysing historical and real-time data, such as bin fill levels, undersize trends, and rake position, the model predicts the likelihood of undersize generation for each bin-dumping event. It then prioritizes partially filled bins over empty ones to minimize fines.

The model integrates with the operator HMI, providing real-time recommendations and compliance tracking. As the model learns from ongoing operations, it continuously improves its predictions, helping to reduce waste, improve raw material utilization, and enhance process efficiency.

Figure 4: Correlation between bin level and undersize generation probability

Challenges in Implementing Digital Twin for Lime Kilns

- Data Integration

Seamless integration of diverse data sources (sensors, PLCs, DCS) into a unified digital twin platform can be complex and resource-intensive.

- Sensor Accuracy and Calibration

Accurate prediction models depend on precise input data. Regular sensor calibration and health monitoring are vital.

- Availability of Historical Data

Machine learning models require extensive, high-quality historical data for training and validation. Gaps or noise in historical records can limit model effectiveness.

- Incomplete Deviation Logs

Failure and abnormality records are often sparse or undocumented, which can affect anomaly detection models.

Conclusion

The deployment of digital twins in lime kilns represents a transformative step toward smarter, safer, and more sustainable steelmaking. By enabling predictive maintenance, real-time quality control, fuel optimization, and anomaly detection, digital twins unlock new levels of process efficiency. While challenges around data and infrastructure persist, the long-term benefits make digital twin integration a worthwhile investment for future-ready steel plants.

References

- Schwab, Klaus. The Fourth Industrial Revolution, World Economic Forum.

- Digital Twin Consortium: https://www.digitaltwinconsortium.org/

- IFAC-PapersOnLine. (2019). "Soft Sensors for Industrial Process Monitoring."

- VDI/VDE 3696: Guidelines for Digital Twin implementation in Process Industry.

Domain-Wise PlantGPT

It is built around purpose-designed micro-agents that collaborate to provide real-time conversational assistance, decision support, and advisory insights tailored to daily plant operations.

Book a Demo →Dx. Consulting Services

Our strength lies in the fusion of deep consulting experience, process domain expertise, and digital execution excellence. This rare combination enables us to go beyond traditional digital transformation.

Book a Meeting →Agentic AI Services

Knowledge Graph as a Service (KGaaS) is a scalable, agent-driven platform that transforms siloed, unstructured, and structured industrial data into a semantically connected, intelligent knowledge network. Built on industry standards and ontologies, the platform enables next-gen applications in root cause analysis, process optimization, SOP automation, and decision augmentation.

Book a Meeting →FAQs

What is a digital twin?

A digital twin is a virtual representation of a physical process, system, or object that simulates its real-time performance using sensor data and AI models.

Why is lime quality important in steelmaking?

Lime acts as a flux, helping remove impurities like silica and phosphorus from molten iron, which is critical for producing high-quality steel.

What is Loss on Ignition (LOI)?

LOI measures the amount of volatile material driven off from lime when heated. It indicates the degree of calcination and is a key quality parameter.

What causes channelling and clustering in kilns?

Uneven material flow or temperature distribution in the packed bed leads to these issues, affecting both product quality and energy efficiency.

How do ML models help in lime kilns?

ML models can analyse historical and real-time data to predict quality, detect anomalies, and optimize fuel usage.

Related Blogs

Data-Driven Optimization of AlF₃ Feed Strategy for Enhanced Efficiency in Aluminum Smelters

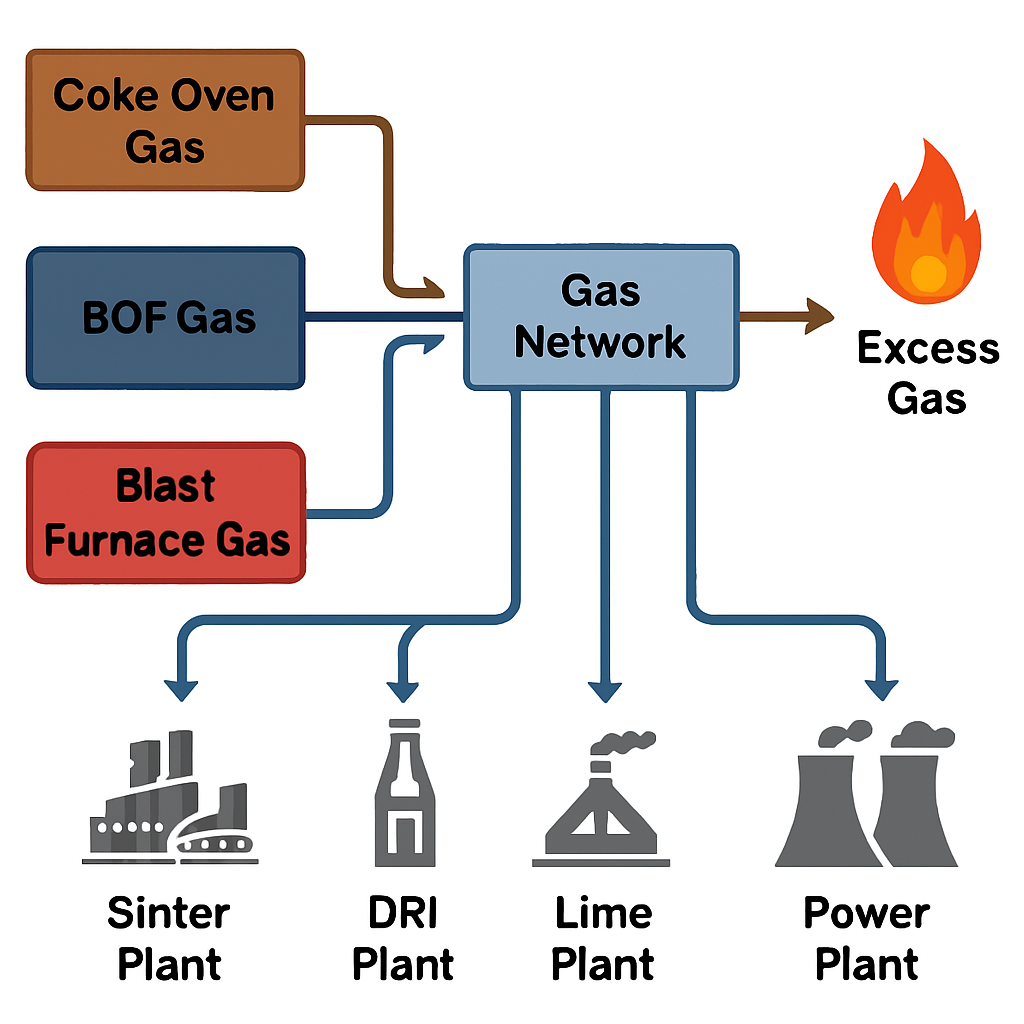

Towards Zero Gas Flaring: Digital Optimization of Industrial Gas Networks

Digital Transformation of Aluminium Pot rooms: AI-Driven Strategies for Pot Health and Efficiency