Modernizing Maintenance Processes with Generative AI in the Manufacturing Industry with OpsEdge

Opsedge is our Gen AI-powered solution that digitizes and optimizes maintenance workflows, integrating seamlessly with your existing systems like CMMS/ERP.

About Us

Tridiagonal.ai, Digital Transformation in Process Manufacturing is a premier Industry 4.0 consultant specializing in Manufacturing Excellence and Digital Transformation. We are an end-to-end execution partner for Chemical 4.0 programs, offering expertise in IT-OT integration, advanced data analytics, energy optimization, and Generative AI. Our capabilities span Digital Transformation Consulting, Process Data Analytics, Process Optimization, and more.

From strategy to implementation and ongoing support, we ensure the success of your digital initiatives. Partner with us to unlock the full potential of your digital investments and drive transformative change in your operations.

How It Works?

How Generative AI Enhances Maintenance Processes with OpsEdge

-

Step 1Inspection Round

-

Step 2Maintenance Work Orders

-

Step 3Planning & Scheduling

-

Step 4Maintenance Execution

-

Step 5Maintenance Dashboard / Report

.gif)

BOOST EFFICIENCY AND SAFETY

Generative AI revolutionizes inspection rounds by automating scheduling, creating smart checklists, and ensuring accurate work orders.

- Smart Scheduling: AI optimizes inspection timing using historical data.

- Focused Checklists: AI targets high-risk areas, enhancing inspection effectiveness.

- Accurate Reporting: Automated reports improve compliance and reduce errors.

- Data-Driven Insights: AI logs and analyzes data, suggesting corrective actions.

Streamline Approvals and Improve Reliability

Generative AI simplifies the approval process by automating tasks, prioritizing work orders, and ensuring compliance.

- Task Prioritization: AI ranks work orders by urgency and impact.

- Compliance Checks: AI validates work orders against safety standards.

- Insightful Reports: AI delivers key insights to refine future processes.

Enhance Accuracy and Speed

Generative AI enhances planning by dynamically adjusting schedules and integrating safety compliance.

- Efficient Allocation: AI ensures optimal resource use.

- Safety Integration: AI embeds compliance into scheduling.

- Continuous Improvement: Real-time adaptability for smooth operations.

EMPOWER TEAMS WITH CONTEXTUAL INTELLIGENCE

Generative AI assists technicians with precise, step-by-step guidance for repairs.

- Tailored Instructions: AI customizes actions based on the situation.

- Safety Compliance: AI ensures adherence to SOPs and standards.

- Faster Repairs: AI speeds up tasks by recommending best practices.

DRIVE INSIGHTS, COMPLIANCE, AND CONTINUOUS IMPROVEMENT

Get a comprehensive view of maintenance performance, costs, and compliance through AI-curated dashboards and insights.

- Real-Time KPIs: Monitor asset health, MTTR, compliance scores, and more.

- Root Cause Analytics: Drill down into failure patterns and causes using AI.

- Automated Compliance Reporting: Streamlined reports for audits, regulations, and governance.

- Continuous Improvement: Recommends process optimizations based on historical trends and outcomes.

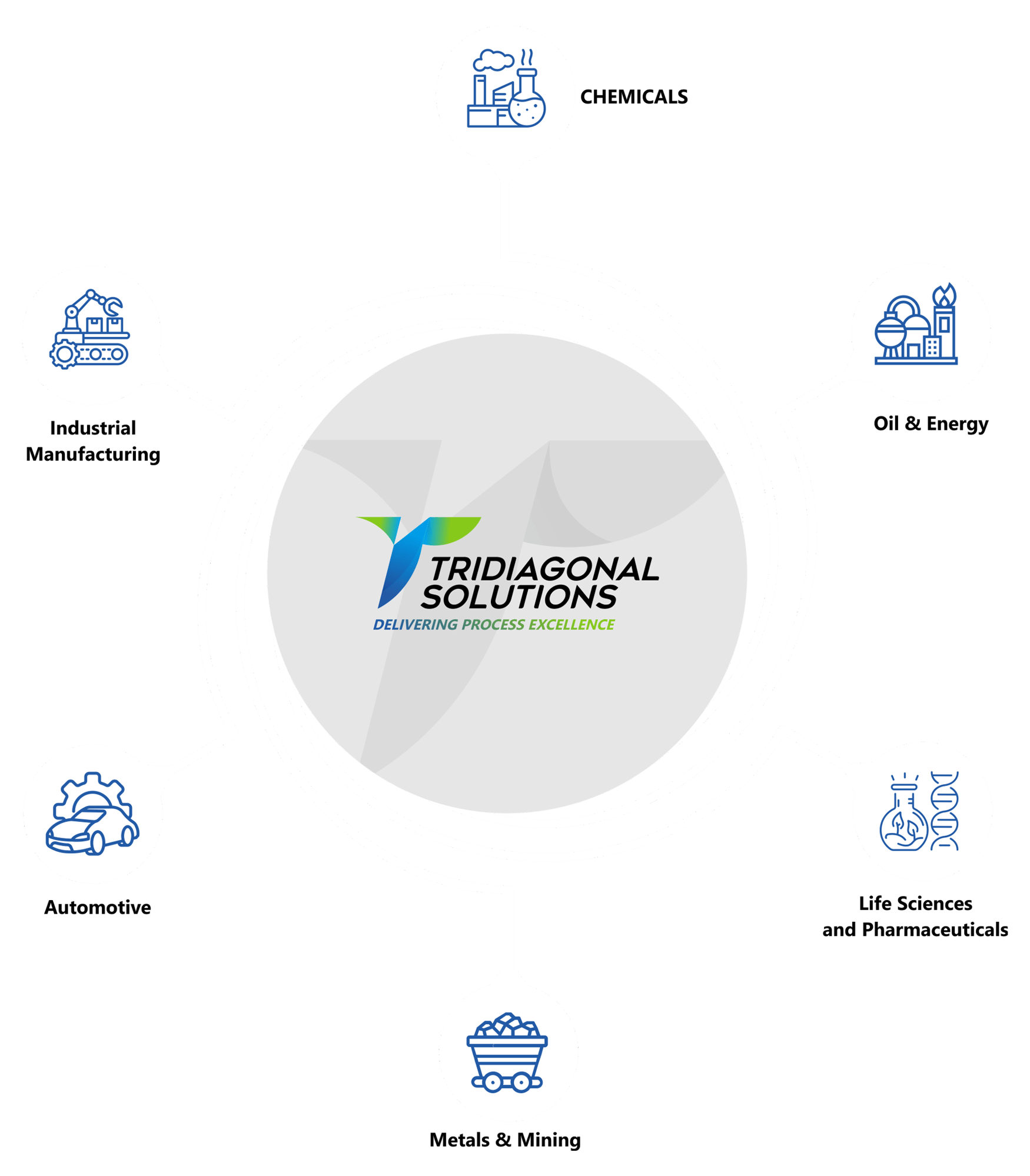

Industries we are transforming with Gen-AI, based on Tridiagonal OpsEdge

Technology Behind the Transformation

Opsedge Features

OpsEdge empowers your business with a suite of advaced features designed to streamline operations and drive growth.

Intuitive Applications

01Provides maintenance teams with user-friendly interface for real-time access to dashboards, work orders, and inventory, streamlining tasks and decision-making on to go.

Maintenance Data Contextualization

02Enables deep contextualization of maintenance data, providing comprehensive insights into equipment health, operational efficiency, and potential risks. This allows for informed decision-making and proactive maintenance strategies.

Gen AI-powered Maintenance Workflow Bot

03Leverages Generative AI to automate maintenance workflows, reducing manual intervention, minimizing errors, and ensuring consistency in maintenance procedures. This streamlines operations and enhances productivity across the plant.

Root Cause Analysis (RCA)

04Facilitates quick identification and resolution of underlying issues by performing in-depth root cause analysis. This capability helps reduce downtime, prevent recurring problems, and improve overall reliability.

Incident Reports

05Streamlines the documentation and management of incidents, ensuring that all issues are tracked, analyzed, and resolved efficiently. This leads to continuous improvement and better compliance with safety standards.

Historical Failure Analysis

06Utilizes historical data to predict potential failures and maintenance needs, allowing for proactive intervention before issues arise. This predictive capability minimizes unexpected downtime and extends equipment lifespan.

Cost optimization and Prediction of Equipment Maintenance

07Provides accurate cost estimation and predictive analytics for equipment maintenance, helping to budget effectively and allocate resources efficiently. This ensures cost-effective maintenance planning and operations.

Key benefits of leveraging Gen AI

Estimated Time Required (Days)

Reduction

Inventory Cost ($)

Reduction

Typical Downtime (Hrs)

Reduction

Total Cost Of Ownership (TCO)

Reduction

Cost Of Downtime

Increase

Planned Vs. Unplanned Maintenance Ratio

Reduction

Energy Consumption

Reduction

Work Order Completion Rate

Improvement

Frequently Asked Questions

How does the application help in reducing maintenance downtime?

By providing real-time access to work orders, inventory data, and predictive insights, the application enables quicker decision-making and more efficient task execution, significantly reducing maintenance downtime.

Can the application be used offline, and will data sync when back online?

Yes, the application supports offline mode, allowing users to continue their tasks without interruption. Once reconnected, all data is automatically synced to ensure accuracy and continuity.

Is the dashboard customizable to fit specific maintenance needs?

Absolutely. The dashboard is fully customizable, allowing teams to prioritize metrics, tasks, and KPIs relevant to their specific workflows and equipment.

How secure is the data accessed and stored through the application?

The application uses advanced encryption protocols and complies with industry standards to ensure secure data transmission, access control, and storage.

Does the application support integration with existing CMMS or ERP systems?

Yes, the application offers seamless API-based integration with most leading CMMS and ERP platforms to maintain workflow continuity and eliminate data silos.

How easy is it to train maintenance teams to use the application?

The application features an intuitive interface, built-in guides, and training resources to help teams adopt it quickly with minimal disruption to operations.

What kind of real-time alerts and notifications does the application provide?

The system sends instant alerts for critical events such as equipment failure risks, overdue maintenance, inventory shortages, and safety violations to keep teams proactive.

Can maintenance tasks be updated directly from the application?

Yes, technicians can log updates, complete work orders, and track task progress directly from the app, ensuring real-time accuracy in reporting and execution.

Curious about how our OpsEdge can streamline your operations?

Book a demo to see how we optimize efficiency and drive results.