Reimagining Aluminium Casthouses with AI: The Next Frontier in Recovery, Quality, and Efficiency

Introduction

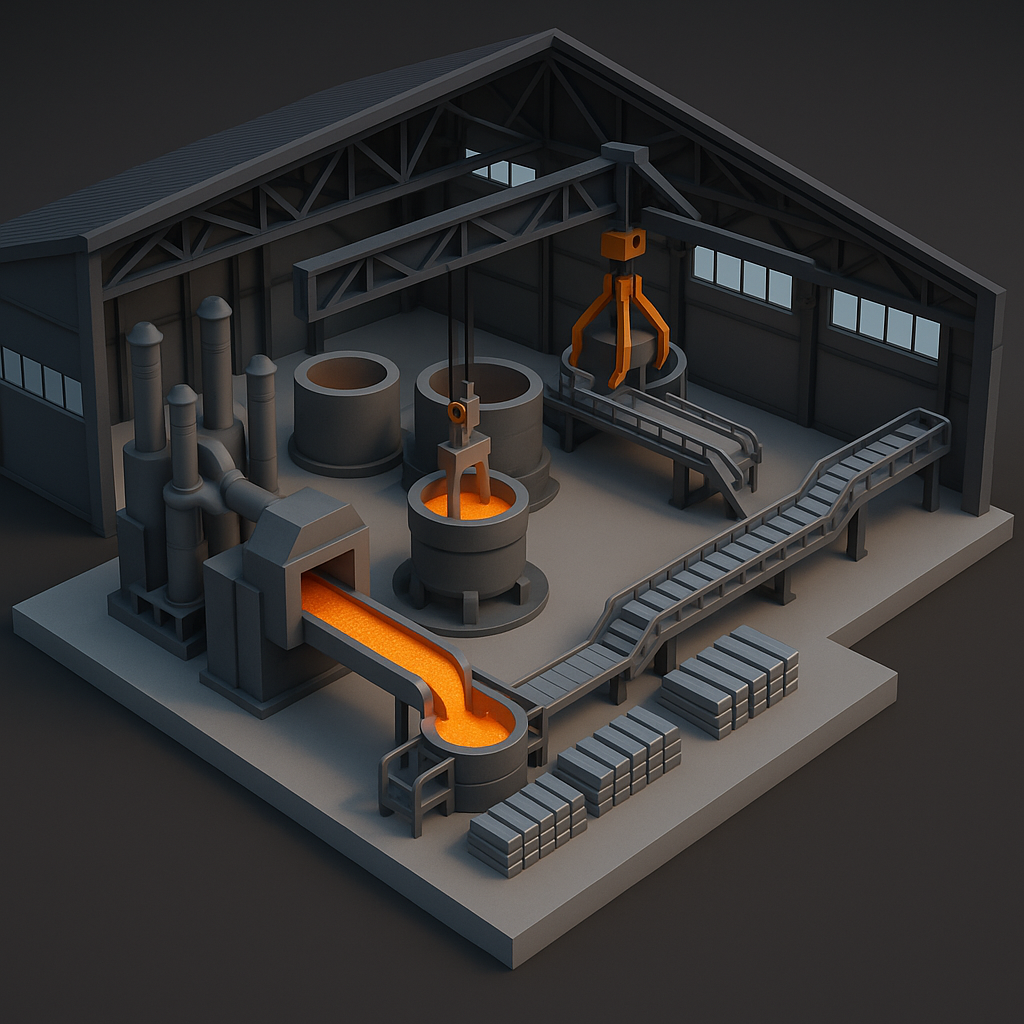

In the aluminium value chain, the casthouse serves as the vital bridge between smelting and downstream fabrication. Here, molten aluminium is refined, alloyed, and cast into semi-finished products such as billets, slabs, and ingots, ready for extrusion or rolling. (Fig 1)

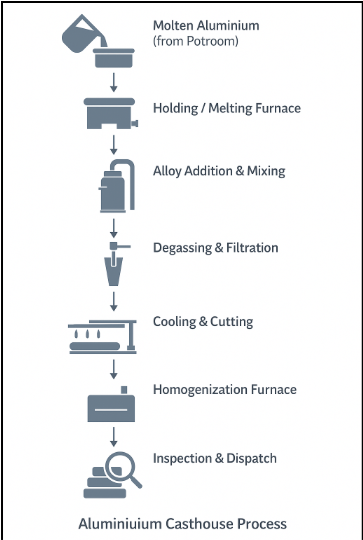

Fig 1: Aluminium casthouse process flowchart

Despite advancements in automation, casthouse operations remain highly dependent on experience-based control. Variables such as melt chemistry, furnace temperature, alloy additions, casting speed, and cooling rate interact in complex, nonlinear ways. Even minor deviations can lead to composition drift, casting defects, or yield losses.

To maintain consistency and competitiveness, aluminium producers are embracing Artificial Intelligence (AI) and Machine Learning (ML) to transform traditional casthouse operations into predictive, data-driven ecosystems.

This article explores the major challenges faced in casthouse control, the limitations of conventional methods, and how AI/ML-based systems can revolutionize chemistry prediction, billet recovery, and process optimization.

The Casthouse Challenge: Balancing Chemistry, Yield, and Quality

A casthouse’s efficiency is determined by how well it can convert molten aluminium into saleable product. Three interrelated performance indicators define this success:

- Casting Recovery: The ratio of approved metal weight to total cast metal.

- Alloy Chemistry Accuracy: Deviation between target and achieved element percentages

- Process Stability: Consistency in casting speed, head & butt lengths, and defect-free logs or slabs.

Even small inefficiencies in these parameters accumulate into significant financial and material losses when multiplied across thousands of heats annually.

Why Do Recovery and Quality Vary?

Variations in billet recovery and alloy chemistry stem from multiple interdependent factors — metallurgical, operational, and environmental.

- Melt Composition Variability

- Inconsistent charge mix or scrap composition introduces elemental imbalance.

- Manual alloy addition control often leads to over- or under-dosing of elements.

- Furnace Temperature Fluctuations

- Uneven heating or burner malfunctions affect melting uniformity and oxidation rates.

- Overheating increases energy costs and element burn-off, while underheating risks incomplete melting.

- Process Parameter Deviations During Casting

- Casting speed, metal head height, and cooling water flow impact solidification quality.

- Improper control leads to surface cracks, butt thickening, or log segregation.

- Human Dependency and Manual Sampling Delays

- Chemistry verification relies on manual sampling and lab analysis every few hours.

- By the time corrective actions are applied, the heat is already cast, leading to wasted effort and yield loss.

Limitations of Conventional Casthouse Control Systems

While PLC and SCADA systems automate many functions, they lack predictive intelligence.

- Process control relies on fixed setpoints and static recipes that do not adapt to changing melt or casting conditions.

- Furnace efficiency, additive recovery, and casting performance are analysed after the fact using reports.

- Operators manually correlate data from multiple systems, limiting speed of decision-making.

In short, the casthouse remains data-rich but insight-poor.

AI/ML-Based Digital Transformation in Aluminium Casthouse Operations

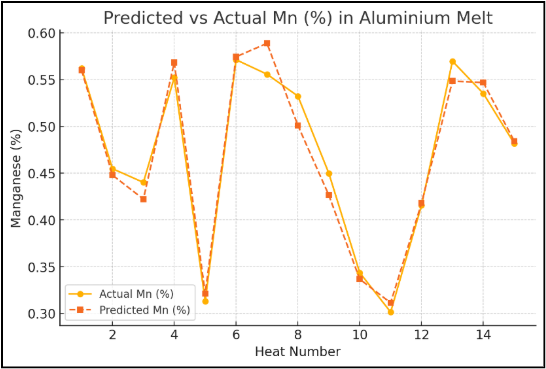

1. Predictive Alloy Chemistry Control

AI models can predict final melt chemistry before sampling, using process variables like:

- Furnace charge composition

- Previous heat chemistry trend

These models act as soft sensors, offering continuous virtual estimates of Si, Fe, Cu, Mn, and Mg levels. Operators receive recommendations for optimal addition adjustments, ensuring the first chemistry sample meets target composition. (Fig 2)

Impact:

- 30 -50% reduction in correction alloys

- Shorter cycle time and improved metal yield

Fig 2: Alloy control comparison

2. Billet Recovery Prediction and Optimization

Machine learning models analyse historical casting data - including plan cast weight, actual head & butt lengths, casting speed, alloy type, and pit efficiency - to predict billet recovery before casting.

By identifying the best operational window for each alloy and furnace, the model recommends optimum casting speeds and butt thickness, preventing yield losses.

Impact:

- 2-3% increase in net recovery

- Reduced scrap and rework costs.

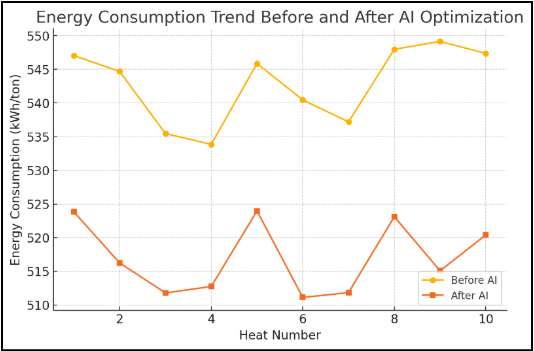

Predictive analytics assess furnace energy consumption per tonne of metal, comparing it to benchmarks derived from historical data.

AI models identify patterns of energy loss or unbalanced firing, recommending burner calibration, flux optimization, or heat scheduling adjustments. (Fig 3)

Impact:

- 5-10% reduction in fuel consumption

- Lower carbon footprint and better furnace utilization

Fig 3: Energy trend comparison

Conclusion

The aluminium casthouse, once dependent on operator intuition and manual feedback, is evolving into a digitally intelligent operation. By combining metallurgical expertise with AI-driven analytics, producers can ensure higher recovery, better quality, and lower operational costs.

The future casthouse will not just cast metal; it will learn, predict, and optimize itself, continuously improving through data. This fusion of metallurgy and machine learning is redefining what it means to be efficient, sustainable, and future-ready.

References

- J. Grandfield, “Modern Trends in Aluminium Casthouse Operations and Automation,” Light Metals, 2022.

- R. Sharma, “AI-Driven Melt Chemistry Control in Aluminium Casting,” TMS Annual Meeting, 2023.

- International Aluminium Institute, “Energy Efficiency and Emission Reduction in Aluminium Production,” 2021.

- M. Hyland & J. Welch, “Alloy Additions and Recovery Mechanisms in Aluminium Melting,” Metallurgical Reviews, 2019.

- N. Verma, “Data-Driven Yield Improvement in Aluminium Casthouses,” ICSOBA Proceedings, 2022.

AI PlantOps

AI PlantOps was built to bridge this gap. It fuses domain intelligence, machine learning, symbolic reasoning, and physics-based validation into one interconnected operating system. The result: a new paradigm of AI PlantOps — where every section, cluster, and workflow is digitally traceable, intelligently optimized, and seamlessly connected.

Book a Demo →Dx. Consulting Services

Our strength lies in the fusion of deep consulting experience, process domain expertise, and digital execution excellence. This rare combination enables us to go beyond traditional digital transformation.

Book a Meeting →Agentic AI Services

Knowledge Graph as a Service (KGaaS) is a scalable, agent-driven platform that transforms siloed, unstructured, and structured industrial data into a semantically connected, intelligent knowledge network. Built on industry standards and ontologies, the platform enables next-gen applications in root cause analysis, process optimization, SOP automation, and decision augmentation.

Book a Meeting →FAQs

Q1. What is billet recovery in aluminium casting?

Billet recovery is the ratio of approved billet weight to total metal cast, representing yield efficiency in the casthouse.

Q2. How can AI predict final melt chemistry?

AI models correlate past chemistry results with process parameters (charge mix, temperature, addition weights) to estimate likely outcomes before sampling.

Q3. What are the main sources of recovery loss in casthouses?

Major contributors include thick butts, scrap generation from surface defects, incorrect alloy additions, and temperature fluctuations.

Q4. How does AI improve energy efficiency in melting furnaces?

Predictive models analyse burner data, flux consumption, and temperature trends to identify inefficiencies and recommend corrective actions.