Model Predictive Control (MPC) for Vacuum Pan Crystallisation

Introduction

Vacuum pan crystallisation is one of the most critical operations in sugar manufacturing. Achieving the target Brix consistently is challenging due to strong nonlinearities, long process delays, and batch-to-batch variability. Traditional PID-based manual control often reacts late, leading to longer batch times and inconsistent product quality.

This blog presents a detailed overview of how Model Predictive Control (MPC) was developed and validated using real plant data from a 120‑MT vacuum pan. The objective: reduce batch time, ensure safe operation, and maintain consistent Brix at the end point.

Problem Statement

Reaching the desired Brix setpoint in a vacuum pan is inherently difficult because:

- The dynamics are slow and highly nonlinear.

- Process variables such as Level, Temperature, and Pressure are strongly coupled.

- Operators adjust steam and feed manually, often leading to overshoot or extended batch times.

As a result, the batch may take longer than required or may fail to reach the desired Brix on time. MPC aims to address these challenges by providing predictive, constraint-aware control.

What is MPC?

Model Predictive Control is an advanced multivariable control technique that:

- Predicts future trajectories of key process variables.

- Optimises manipulated variables such as Steam, Steam Temperature, Feed, and Outlet flow.

- Enforces all operational constraints explicitly.

- Computes the optimal move but applies only the first step, re-optimising at the next time step.

Because MPC is predictive rather than reactive, it is highly suited for slow and interacting systems like vacuum pans.

Why MPC for Vacuum Pan Crystallisation?

Vacuum pans exhibit:

- Strong interactions between variables

- High nonlinearity

- Slow response and long delays

- Operator-induced variability

Changes in steam affect not only Brix but also Level, Temperature, and Pressure. MPC handles these dynamic interactions better than PID by predicting the future effects of each move and optimising accordingly.

Fig.1 MPC approach

Fig.1 MPC approach

Plant Data Collection & Preprocessing

Plant data was collected over 2 months (1464 hours). Variables measured:

- Brix

- Pan Level (%)

- Temperature (°C)

- Pressure (kg/cm²)

- Steam Flow (kg/hr)

- Steam Temperature (°C)

- Feed Flow (kg/hr)

- Outlet Flow (kg/hr)

Data underwent preprocessing to remove outliers, handle missing values, and normalise ranges. The cleaned dataset was used for model identification.

MPC Structure

Controlled Variables (CVs):

- Brix (primary target)

- Level

- Temperature

- Pressure

Manipulated Variables (MVs):

- Steam Flow

- Steam Temperature

- Feed Flow

- Outlet Flow

Prediction Horizon = 3 hours (matching typical batch duration)

Control Horizon = 1 hour (aligned with practical operator actions)

Constraints:

- Level ≤ 100% (safety)

- Steam, Feed, Outlet within plant limits

- Temperature and Pressure within ±5°C and ±0.5 bar margins

- Soft constraint on Brix = 100°Bx to allow feasible optimisation

Model Identification:

A state‑space/ARX model was developed using preprocessed plant data. Validation through correlation plots and step‑response trends confirmed the model’s ability to capture key dynamics and interactions.

This model was integrated into the MPC framework to simulate and optimize vacuum pan performance.

MPC Results & Interpretation

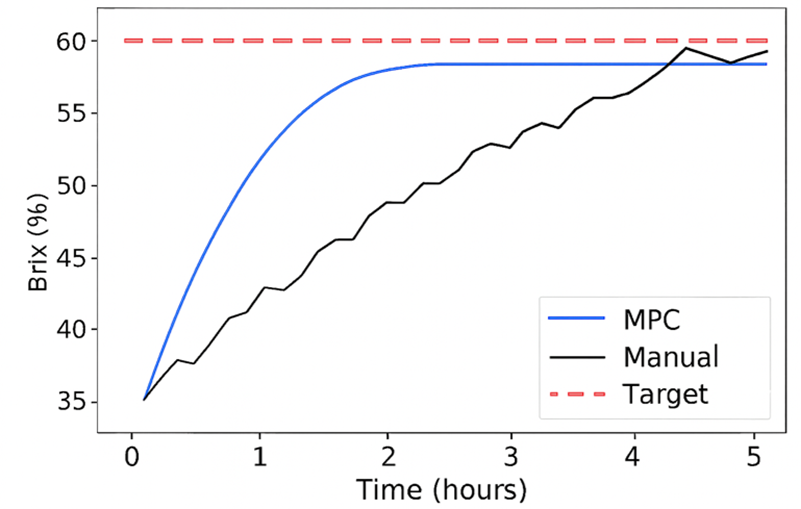

Fig.2 MPC vs Manual control

Key observations:

- MPC achieves target Brix (~58°Bx in study) within ~3 hours, compared to ~4 hours manually.

- Level remains within safety limits due to constraint handling.

- Temperature and Pressure stay stable, indicating no oscillations or unwanted disturbances.

- Manipulated variables move smoothly without abrupt changes.

Overall, MPC provides faster, safer, and more consistent operation than manual control.

Conclusion

MPC proved to be stable, practical, and effective for vacuum pan crystallisation. The controller:

- Reduces batch time by ~1 hour

- Increases throughput

- Minimises operator dependency

- Improves consistency and batch quality

- Ensures safe operation under all constraints

The results demonstrate that MPC is a robust solution for modernising crystallisation operations.

References

- C. E. García, D. M. Prett, M. Morari,

Model Predictive Control: Theory and Practice—A Survey, Automatica, 1989.

https://doi.org/10.1016/0005-1098(89)90002-2 - S. J. Qin, T. A. Badgwell,

A Survey of Industrial Model Predictive Control Technology, Control Engineering Practice, 2003.

https://doi.org/10.1016/S0967-0661(02)00186-7 - D. E. Seborg, T. F. Edgar, D. A. Mellichamp, F. J. Doyle,

Process Dynamics and Control, Wiley, 4th Edition.

https://www.wiley.com/en-in/Process+Dynamics+and+Control%2C+4th+Edition-p-9781119582089 - J. B. Rawlings, D. Q. Mayne,

Model Predictive Control: Theory and Design, Nob Hill Publishing, 2009.

https://jbrwww.che.wisc.edu/papers/book.pdf

AI PlantOps

AI PlantOps was built to bridge this gap. It fuses domain intelligence, machine learning, symbolic reasoning, and physics-based validation into one interconnected operating system. The result: a new paradigm of AI PlantOps — where every section, cluster, and workflow is digitally traceable, intelligently optimized, and seamlessly connected.

Book a Demo →Dx. Consulting Services

Our strength lies in the fusion of deep consulting experience, process domain expertise, and digital execution excellence. This rare combination enables us to go beyond traditional digital transformation.

Book a Meeting →Agentic AI Services

Knowledge Graph as a Service (KGaaS) is a scalable, agent-driven platform that transforms siloed, unstructured, and structured industrial data into a semantically connected, intelligent knowledge network. Built on industry standards and ontologies, the platform enables next-gen applications in root cause analysis, process optimization, SOP automation, and decision augmentation.

Book a Meeting →FAQs

Q: How is MPC different from traditional PID control?

A: PID reacts only to current error, while MPC predicts future behavior using a process model. MPC accounts for constraints (e.g., Level ≤ 100, MV limits) and optimizes all variables together, making it better suited for multivariable evaporator control.

Q: What inputs are required for MPC in a vacuum pan/evaporator?

A: MPC uses the existing plant measurements:

- CVs: Brix, Level, Temperature, Pressure

- MVs: Steam flow, Steam temperature, Feed rate, Outlet rate

All signals already exist in the DCS, so no new instrumentation is needed.

Q: Why is Brix control difficult with PID or operator control?

A: Brix rises non-linearly and responds with a large time delay, especially near the end of the batch. Steam–feed interactions also create cross-coupling. PID cannot predict this evolution, but MPC anticipates the trajectory and adjusts MVs early.

Q: Can MPC adapt if operating conditions change?

A: Yes. Data-driven MPC models can be re-identified periodically using new batch data. This requires only routine historian data, and retraining is much easier than building full first-principles models.

Q: Why do batches often take longer than necessary?

A: Operators typically use a fixed steam pattern or conservative cycle time to avoid under-concentration. Without predictive visibility of future Brix, the system is often over-steamed or delayed. MPC helps by planning the full batch trajectory, reducing cycle time while ensuring targets are met.

Related Blogs