The Invisible Factory: How AI Is Exposing Hidden Losses in Metal, Mining & Cement Plants

- Introduction

- Where the Invisible Factory Hides?

- Why the Invisible Factory Exists?

- How AI Makes the Invisible Visible?

- Real Industrial Examples from My Work

- Advanced Digital Technologies Enabling Predictive Operations

- The Future: Building a Visibility Layer Above Automation

- Final Thought: Make the Invisible Factory Visible

Introduction

The Two Factories Operating Inside Every Plant

Walk into the control room of any steel, cement, or mining operation, and you will hear a reassuring statement from operators and supervisors:

“Our process is stable. We are doing fine.”

On the surface, this seems true: DCS screens stay green. Alarms are manageable. KPIs appear within acceptable limits. It feels as though operations are stable and predictable.

However, beneath this visible layer lies a very different version of the process, one that is complex, dynamic, and prone to hidden instabilities. This second version of the plant is not captured fully by traditional automation systems. While one factory is seen through dashboards, historian plots, and alarm summaries, the real version of the factory is unfolding in parallel, driven by variations and interactions that are too subtle or too slow for human operators to notice.

- The first version: The factory you think you are running is based on what is easily observable, the production reports, DCS trends, energy dashboards, and real-time alarms. In this version, everything looks manageable and under control.

- The second version: The factory that is actually running is shaped by factors such as micro-instabilities, slow and cumulative thermal drifts, hidden heat losses, raw-material quality fluctuations, nonlinear process interactions, and subtle equipment degradation. These disturbances are often too weak to trigger alarms and too complex to interpret without advanced analytics. Yet they silently accumulate, affecting energy efficiency, production stability, quality consistency, and overall throughput.

This deeper, hidden layer is what we call the Invisible Factory. It is responsible for losses that rarely appear in daily reports and that operators cannot detect because they are distributed over time, masked by routine patterns, or concealed within noisy data. Even small deviations that seem harmless can add up to large financial losses across months of continuous operation. In reality, the Invisible Factory quietly drains crores of rupees every year without most plants even realizing it.

Where the Invisible Factory Hides?

The Invisible Factory manifests differently across industries, but the underlying patterns of hidden losses are remarkably similar.

2.1 Invisible Losses in Cement Plants

In cement plants, the kiln is often perceived as stable, yet small and frequent fluctuations in kiln draft can significantly reduce heat transfer efficiency. These oscillations are typically too minor to appear in daily reports but have long-term consequences. Variability in raw-meal chemistry, such as changes in silica, alumina, or lime saturation, can subtly shift free lime or SO₃ levels in clinker. These changes are rarely detected early through regular DCS trends.

Similarly, grinding mills often experience gradual increases in vibration due to feed granulometry changes or progressive liner wear. While this may not raise immediate alarms, it increases energy consumption and reduces grinding efficiency. When plants rely heavily on Alternative Fuels and Raw materials (AFR), even small fluctuations in AFR feed quality or combustion characteristics can destabilise the burning zone and impact clinker formation.

2.2 Invisible Losses in Steel & Metal Plants

In steel plants, processes such as blast furnace operation, reheating, and melting are especially prone to hidden losses. Gas channelling in blast furnaces, for instance, begins with subtle shifts in raceway temperature and pressure that are impossible for operators to detect manually. These early indicators never appear as alarms but later lead to significant instability and higher coke rates.

Reheating furnaces also suffer from hidden inefficiencies. Fuel overshoot caused by uneven zone behaviour or inconsistent furnace load results in unnecessary consumption of energy. Temperature drifts within furnaces often begin hours before visible swings appear on DCS screens. Because the early signals are subtle, the plant continues operating under the illusion of stability while invisible losses accumulate.

2.3 Invisible Losses in Mining Plants

Mining operations, particularly grinding and flotation circuits, face similar issues. Grinding mills frequently operate at suboptimal load due to small variations in feed density or ore hardness. These fluctuations do not trigger alarms but lead to significant power inefficiency. In flotation circuits, slight deviations in pulp density or air flow may go unnoticed but can cause a substantial drop in recovery. Cyclone misclassification is another major source of hidden loss; its early signatures rarely appear in SCADA systems, yet it directly impacts downstream flotation performance and product grade.

Across these industries, the Invisible Factory remains active and influential, quietly reducing efficiency and profitability.

Why the Invisible Factory Exists?

There are three primary reasons why hidden losses persist and remain difficult to capture.

3.1 Too Much Data, Too Little Interpretation

Modern plants collect thousands of data points from sensors, analyzers, and control systems. However, operators typically monitor only a small subset of these, usually fewer than 50 variables that appear on their core screens. The majority of data remains unexamined or underutilized. Important signals get buried within noise, and deeper patterns never emerge through manual inspection.

3.2 Complex Interactions Between Variables

Industrial processes involve complex interdependencies. A small change in one variable may propagate through the system, affecting multiple other variables across units. DCS systems treat each tag independently, but real-world processes do not behave independently. For example, in cement kilns, a slight shift in raw-meal chemistry may increase free lime, which in turn affects burning zone temperature, which then alters fuel consumption and ultimately influences emissions. Such chains of interactions remain invisible in standard control-room views.

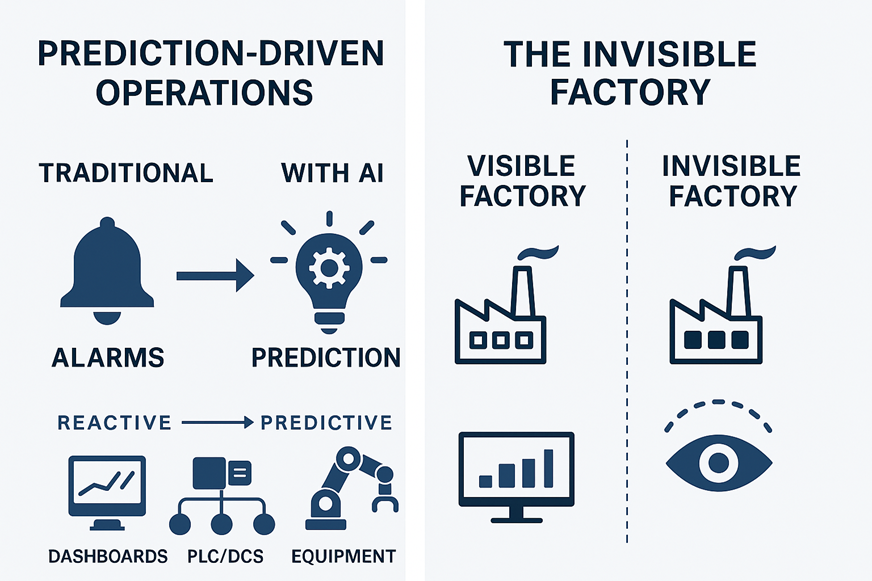

3.3 Absence of a Predictive Layer

Traditional automation systems are designed to react, not predict. Alarms alert only after thresholds are crossed. Operators intervene only when deviations become visible. There is no intelligence layer that warns the plant about what will happen in the next few hours if conditions continue unchanged. Without this predictive capability, small deviations escalate into larger issues before action is taken.

How AI Makes the Invisible Visible?

AI technologies, especially machine learning, deep learning, and advanced process analytics, offer capabilities that traditional automation cannot. They can detect weak signals buried inside noisy data, learn patterns from historical behaviour, predict future deviations, and identify root causes that are not evident to operators.

“AI behaves like an industrial CT-scan.”

Looking beneath the surface of data and revealing patterns deep within the process. Models can identify shifts in thermal signatures in steel plants, predict process instability in cement kilns hours before it occurs, and detect subtle nonlinear interactions that affect grinding efficiency in mining.

By quantifying the impact of hidden drifts, AI not only highlights loss hotspots but also recommends optimized setpoints to stabilize the process. The plant transitions from a reaction-based mode to a prediction-based mode. Operators intervene long before deviations become serious, reducing downtime and improving consistency.

Fig: Prediction Driven Vs Invisible Factory

Real Industrial Examples from My Work

5.1 Steel and Metal

In blast furnace operations, AI detected early signs of gas channelling nearly 30–45 minutes before any visible imbalance. This allowed operators to adjust burden distribution in time, preventing instability and reducing coke rate. Furnace temperature forecasting models predicted thermal drift four to six hours ahead, enabling proactive corrective action. In reheating furnaces, AI learned complex zone interactions and optimized burner patterns, leading to significant fuel savings and better rolling performance.

5.2 Cement

AI-driven kiln stability forecasting identified oscillations and ring-formation behavior early enough to prevent major disturbances. Clinker quality models predicted free lime and SO₃ well in advance, enabling more stable chemistry control. AI also reduced mill vibration and power consumption by identifying hidden load patterns, while AFR stability models forecasted potential instability resulting from fuel variations.

5.3 Mining

In grinding operations, AI revealed inefficiencies caused by subtle interactions between ore hardness, density, and mill load. These insights enabled a 3–7% improvement in performance, an exceptionally impactful gain in mining operations.

Advanced Digital Technologies Enabling Predictive Operations

Achieving predictive operations requires more than forecasting alone. Technologies such as Model Predictive Control (MPC), state-space models, soft sensors, digital twins, and variability reduction frameworks build a robust predictive ecosystem. These tools create a digital visibility layer above traditional PLC/DCS systems continuously monitoring, diagnosing, predicting, and optimizing the process in real time.

The Future: Building a Visibility Layer Above Automation

Many plants assume digitalization is about dashboards and historical trends. In reality, dashboards capture only the visible part of the factory. The true transformation occurs when a predictive, AI-driven visibility layer is integrated above automation one that delivers early warnings, predicts stability, detects drifts, recommends optimizations, and quantifies micro-losses.

This layer does not replace automation. It enhances it.

Final Thought: Make the Invisible Factory Visible

The greatest opportunity for industrial performance improvement does not require major capex, new equipment, or additional sensors. It requires a shift in visibility. When the Invisible Factory becomes visible, energy reduces, quality stabilizes, throughput increases, and equipment life extends. Production becomes predictable, operators gain confidence, and EBITDA rises all without altering the physical process.

This is the future of industrial excellence:

a future defined by prediction, visibility, and intelligence.

AI PlantOps

AI PlantOps was built to bridge this gap. It fuses domain intelligence, machine learning, symbolic reasoning, and physics-based validation into one interconnected operating system. The result: a new paradigm of AI PlantOps — where every section, cluster, and workflow is digitally traceable, intelligently optimized, and seamlessly connected.

Book a Demo →Dx. Consulting Services

Our strength lies in the fusion of deep consulting experience, process domain expertise, and digital execution excellence. This rare combination enables us to go beyond traditional digital transformation.

Book a Meeting →Agentic AI Services

Knowledge Graph as a Service (KGaaS) is a scalable, agent-driven platform that transforms siloed, unstructured, and structured industrial data into a semantically connected, intelligent knowledge network. Built on industry standards and ontologies, the platform enables next-gen applications in root cause analysis, process optimization, SOP automation, and decision augmentation.

Book a Meeting →FAQs

1. What is the Invisible Factory?

The Invisible Factory is the hidden layer of process behavior where small instabilities, slow drifts, and complex interactions occur without triggering alarms, yet silently cause energy loss, quality variation, and reduced throughput

2. Why don’t traditional DCS and KPIs capture these losses?

Because most losses develop gradually and remain within acceptable limits. Traditional systems react only to threshold violations, while invisible losses accumulate quietly over time and stay masked inside normal-looking trends

3. How does AI make these hidden losses visible?

AI detects weak signals buried in noisy data, learns multivariable interactions, and predicts future deviations hours in advance revealing problems long before they become operationally obvious

4. Does AI replace operators or automation systems?

No. AI acts as a predictive visibility layer above existing automation, supporting operators with early warnings, forecasts, and optimization insights while control authority remains unchanged

5. What business impact does exposing the Invisible Factory deliver?

By addressing hidden losses, plants achieve lower energy consumption, more stable quality, higher throughput, and improved profitability—often without adding new equipment or sensors

Related Blogs

The Human Side of AI: Why Shop-Floor Adoption Is Harder Than Model Building

Bridging AI and Control: Surrogate Models for Dynamic Process Optimization