Data-Driven Optimization of AlF₃ Feed Strategy for Enhanced Efficiency in Aluminum Smelters

Introduction

Aluminium smelting is one of the most energy-intensive metallurgical processes, with electricity costs accounting for a significant portion of total production expenses. In the Hall–Héroult process, stable bath temperature is essential for maintaining current efficiency, minimizing anode effects, and ensuring consistent metal quality. Aluminium fluoride (AlF₃) plays a critical role in regulating bath liquidus temperature and electrical conductivity. Despite its importance, many smelters continue to rely on legacy rule-based controllers and operator heuristics for AlF₃ addition, which often fail to capture nonlinear interactions among process variables. With the availability of high-resolution operational data, data-driven optimization presents an opportunity to significantly improve AlF₃ feed strategies.

Role of AlF₃ in Aluminium Smelting

AlF₃ is used to adjust the cryolite ratio of the electrolyte, thereby influencing bath liquidus temperature, resistivity, and alumina solubility. Insufficient AlF₃ addition results in higher bath temperatures and increased power consumption, while excessive AlF₃ can cause sludge formation, cathode wear, and operational instability. Precise control of AlF₃ feed is therefore essential for balancing energy efficiency and cell health.

Data Collection and Feature Engineering

This study utilized historical data from more than 100 smelting pots over a four-year period. Key parameters included pot age, alumina feed rate, cell voltage, bath temperature, excess AlF₃ percentage, and tapping frequency. Mutual information analysis was applied to identify variables with the strongest influence on AlF₃ consumption, enabling effective feature selection for model development.

Machine Learning Model Development

Multiple regression and machine learning models were evaluated, including linear regression, decision trees, and random forest regression. Models were trained and validated using historical data splits across multiple pots. The random forest model demonstrated superior performance, achieving an R² of 0.93 and a mean absolute error of 6.6, indicating strong predictive capability for AlF₃ feed requirements.

Recommender System Implementation

The final model was deployed as an operator-facing recommender system that provides optimal AlF₃ dosing guidance based on current process conditions. Rather than replacing existing control systems, the recommender complements them by offering actionable insights, improving bath temperature stability, and reducing excess AlF₃ variability.

Fig 1: Hall–Héroult cell schematic illustrating AlF₃ influence on bath temperature.

Energy and Economic Benefits

A 1% improvement in current efficiency corresponds to approximately 145 kWh per metric ton of aluminium saved. This translates to an estimated cost saving of about $4.78 per ton of aluminium produced. At the plant scale, these savings result in significant annual economic and sustainability benefits.

Fig 2: Machine learning workflow for AlF₃ feed optimization

Conclusion

The presented data-driven framework demonstrates the effectiveness of machine learning in optimizing AlF₃ feed strategy for aluminium smelting. By leveraging historical data and predictive analytics, smelters can achieve improved bath stability, enhanced current efficiency, and reduced energy consumption. The approach is scalable, interpretable, and well-suited for industrial deployment.

References

- Grjotheim, K., Kvande, H. Introduction to Aluminium Electrolysis. Aluminium-Verlag, 1993.

- Thonstad, J. et al. Aluminium Electrolysis: Fundamentals of the Hall–Héroult Process. Aluminium-Verlag, 2001.

- Breiman, L. Random Forests. Machine Learning, 2001.

AI PlantOps

AI PlantOps was built to bridge this gap. It fuses domain intelligence, machine learning, symbolic reasoning, and physics-based validation into one interconnected operating system. The result: a new paradigm of AI PlantOps — where every section, cluster, and workflow is digitally traceable, intelligently optimized, and seamlessly connected.

Book a Demo →Dx. Consulting Services

Our strength lies in the fusion of deep consulting experience, process domain expertise, and digital execution excellence. This rare combination enables us to go beyond traditional digital transformation.

Book a Meeting →Agentic AI Services

Knowledge Graph as a Service (KGaaS) is a scalable, agent-driven platform that transforms siloed, unstructured, and structured industrial data into a semantically connected, intelligent knowledge network. Built on industry standards and ontologies, the platform enables next-gen applications in root cause analysis, process optimization, SOP automation, and decision augmentation.

Book a Meeting →FAQs

Q1. Can this model be applied to different smelters?

Yes, with retraining using site-specific data.

Q2. Does it replace existing control systems?

No, it complements existing controllers as a decision-support tool.

Q3. What data duration is required?

Typically, 1-2 years of high-quality operational data.

Q4. What is the primary benefit?

Improved energy efficiency and reduced bath temperature variability.

Related Blogs

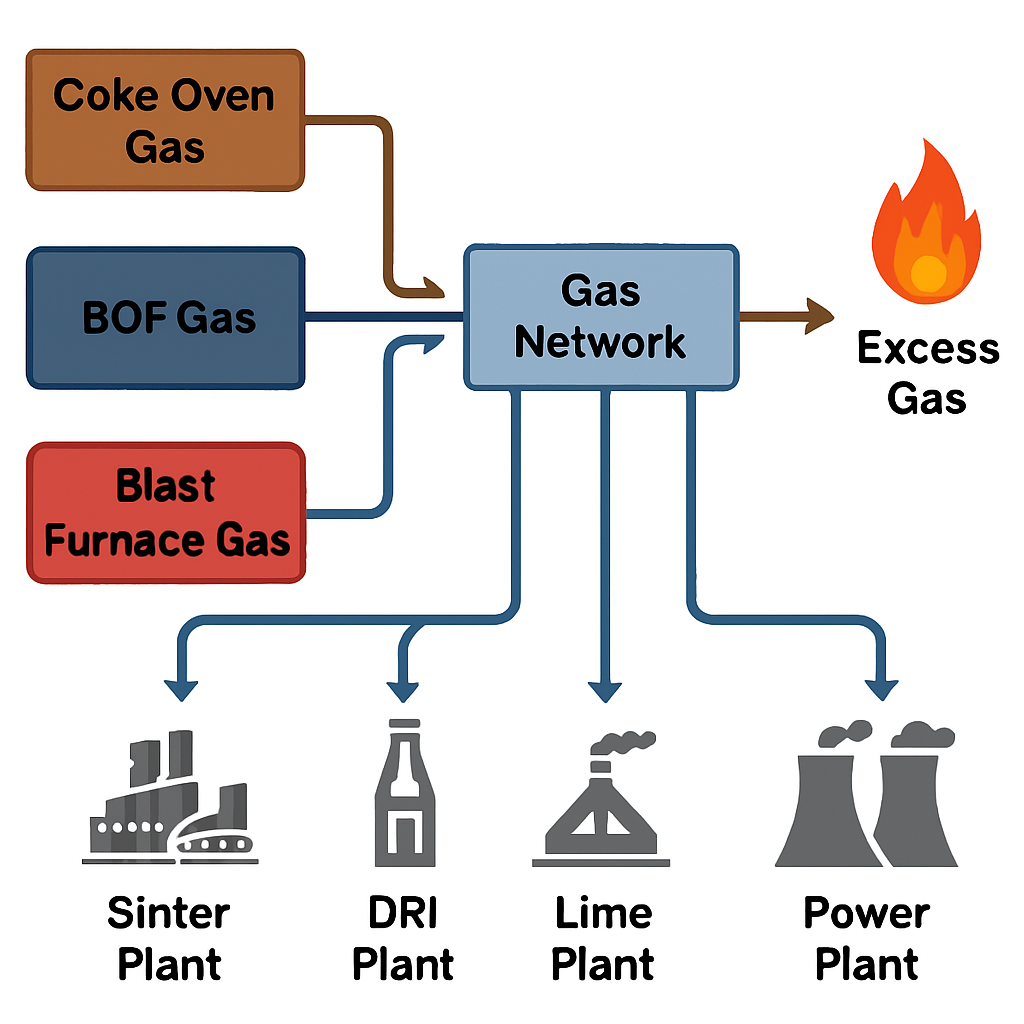

Towards Zero Gas Flaring: Digital Optimization of Industrial Gas Networks

Digital Transformation of Aluminium Pot rooms: AI-Driven Strategies for Pot Health and Efficiency

Supercharging Lime Kiln Operations with Digital Twin and AI Innovation