Use Cases / Case Studies

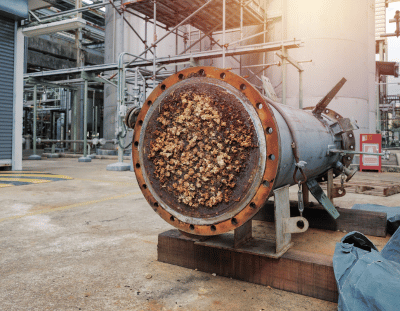

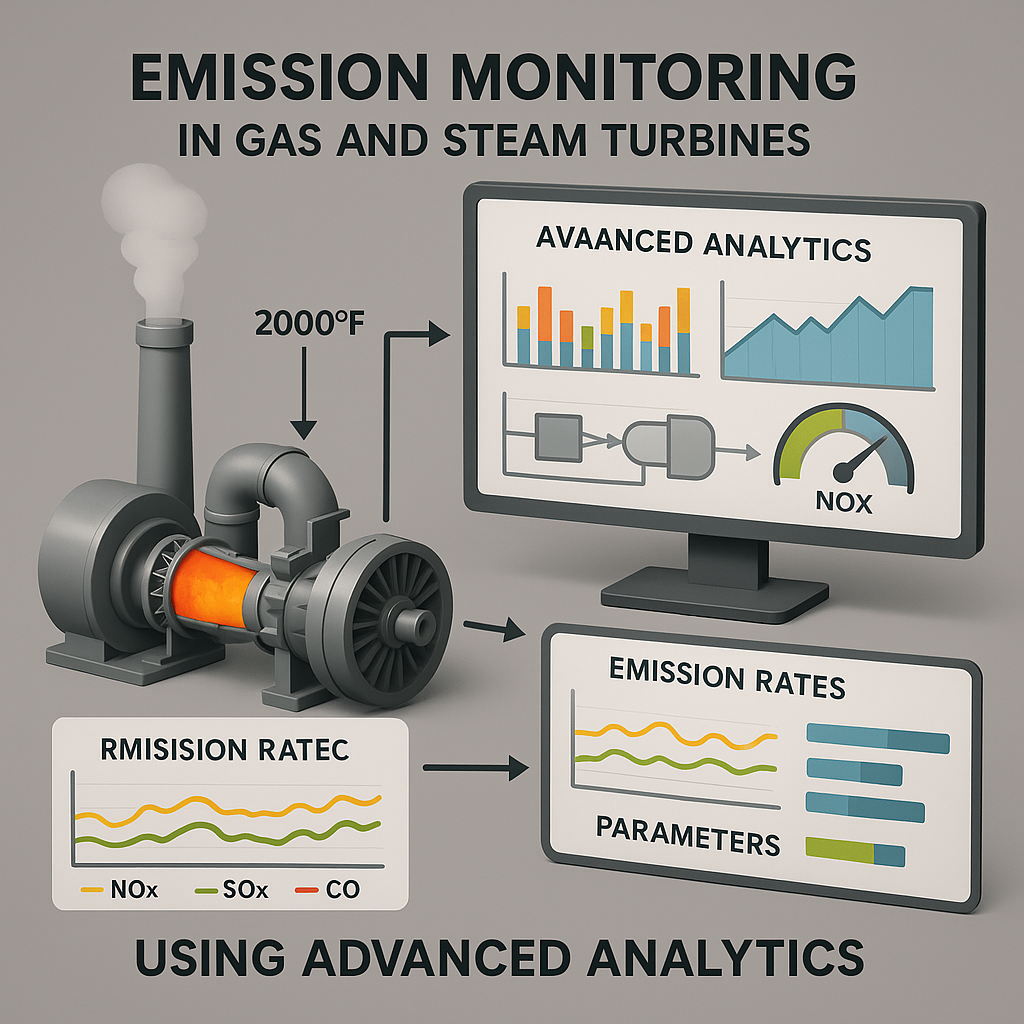

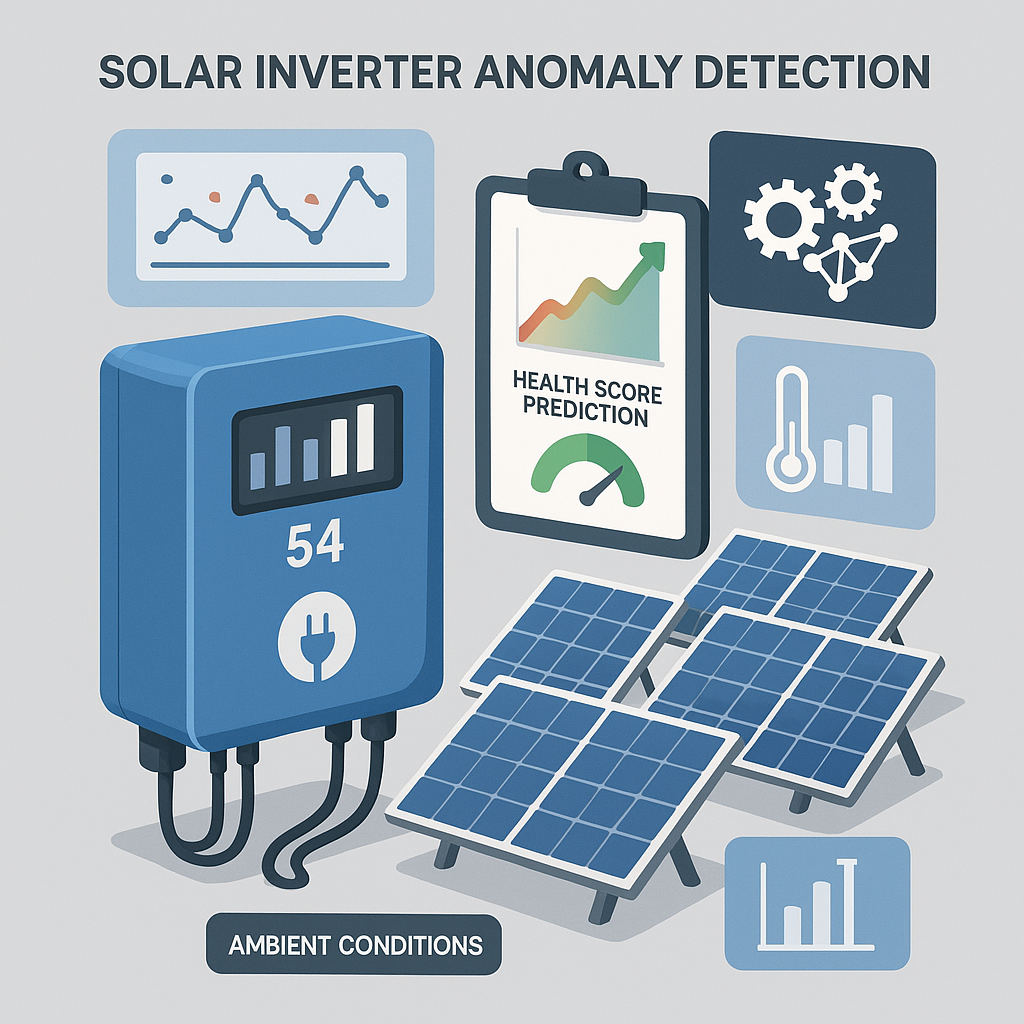

Oil, Gas & Energy

Life Sciences/Pharma

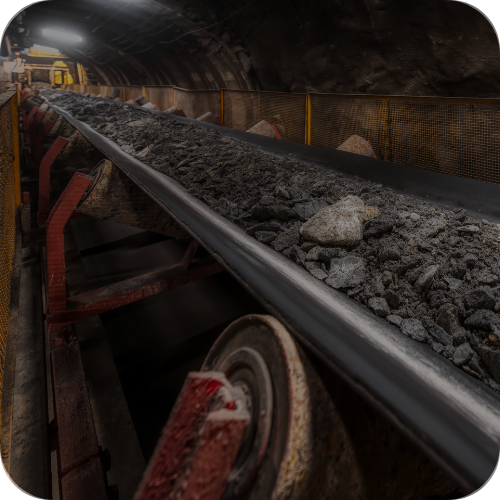

Metals, Mining & Cement

Food & Beverages

Chemicals & Petrochemicals

Resource Type

Industry

Date Range

Showing 0 results

No resources found

Try adjusting your filters or search term

.webp)

.webp)