What we do

Dx. Consulting Services

Domain-Driven, Use Case-Centric, and Ready for Production

Our Dx Consulting Services are built to accelerate digital transformation for industrial enterprises—bridging the gap between operational challenges and scalable AI solutions.With deep roots in engineering sciences and industrial systems, we help clients chart transformation journeys that are both technically sound and business-aligned.

Digital Transformation Consulting – Process Manufacturing

Tridiagonal.AI is a trusted partner for successful manufacturing excellence, digital transformation strategy and implementation of digital / Industry 4.0 tech stacks in process manufacturing. Our process domain understanding, technology expertise and hands-on implementation experience enables us to take deeper view to devise sustainable Dx strategy and roadmap.

Core Expertise: Digital transformation for Production / Process Optimization, Energy Optimization, Quality Prediction,Predictive maintenance and Safety & Sustainability.

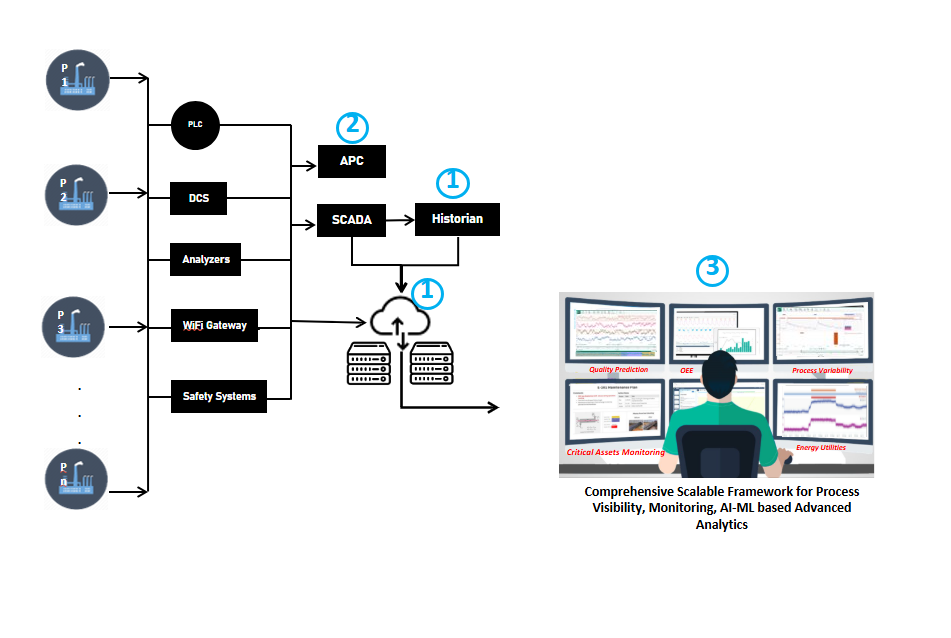

- Understanding the scope (requirement): Current V/S Expected performance (IT-OT)

- Whether or not the current infrastructure is I-4.0 ready

- How the current data architecture looks like; Sensors, DCS/SCADA, etc.

- Additional sensor Implementation for I 4.0 use cases

- Whether the entity of Data Infra is OPC compliant/evaluating the communication protocols supported

- Identification of IT-OT Data requirement Tech Stack

- Designing ISA 95 compliant IT-OT architecture

Domains: MES, Historians, Industry Data Ops, IT-OT integration, Cloud infrastructure, Unified namespace architecture (UNS), ISA 95, Asset hierarchy

Dx Tech Stacks: IT-OT assessment, Advanced process control / AI-based Process control, Predictive Analytics, Energy Management (Scope 1 & 2), Digital workforce

Industry Data Ops is our specialized approach to managing and mobilizing industrial data across engineering, operations, and enterprise systems. Our focus is on enabling trusted, contextualized, and real-time data that powers AI-driven decision-making at scale.

Benchmarking few key performance metrics and Zone to Win- To define Vision, Mission, Goals, Digital Culture, Talent & Skills, Technology Leadership, etc.

- Identifying the pain areas in Process manufacturing

- Blueprinting Dx - Defining the Process Problem Statements – production/ process optimization, Maintenance, Quality, Safety, Sustainability

- Creation of business Case for operational benefits

Operations Areas: Manufacturing planning & schedule, Quality, Overall yield, Zero defects, Energy optimization, OEE, etc.

Financial Analysis - Projected Savings, Benefits report, ROI assessment

- Creating the financial savings report-projected savings per asset/process

- Business case(s) for various tech stack implementations for each identified areas (Process optimization, Maintenance, Quality, Safety, Sustainability)

- Assessment of the required budget

- Estimated savings in the CAPEX, OPEX

- Dx investment planning for 5 years with IRR / NPV / Payback period calculations

For e.g. ROI, Pay-back period, Investment planning, Capex-Opex budget allocation

Develop Priority Matrix depending on the Digital Maturity Assessment, Availability of Assets, Process, People

- Prioritizing the Business problems based on the savings, requirements and challenges

- Identification of Dx Tech Stack(s) for implementation

- Implementation plan and risk mitigation strategy

- Change management

- Industry 4.0 training needs identification

- Cultural transformation roadmap

For e.g. Prioritisation matrix, Dx roadmap, Cultural transformation, Training

PMC for Implementation of Solution(s) – Continuous efforts for e.g., IT-OT integration, Sensor Placements, APC, APM, OTS, Digital Workforce, Others

- Develop Scalability Framework

- Implementation roll-out plan across different locations

- Continuous Improvement - Gap Analysis and Scope of Improvement – KPIs, New / Advanced Use Cases

- Evaluation of Usage of the solution implements

- Post implementation benefit analysis/ ROI calculations

- Identification of gaps in solutions that are implemented and rectification plan

- Identification of Training needs

- New Use Cases definition, New modeling framework, Advanced Analytics, etc.

PMC: Ensuring successful Dx implementation and post-implementation ROI’s

- Understanding the scope (requirement): Current V/S Expected performance (IT-OT)

- Whether or not the current infrastructure is I-4.0 ready

- How the current data architecture looks like; Sensors, DCS/SCADA, etc.

- Additional sensor Implementation for I 4.0 use cases

- Whether the entity of Data Infra is OPC compliant/evaluating the communication protocols supported

- Identification of IT-OT Data requirement Tech Stack

- Designing ISA 95 compliant IT-OT architecture

Domains: MES, Historians, Industry Data Ops, IT-OT integration, Cloud infrastructure, Unified namespace architecture (UNS), ISA 95, Asset hierarchy

Financial Analysis - Projected Savings, Benefits report, ROI assessment

- Creating the financial savings report-projected savings per asset/process

- Business case(s) for various tech stack implementations for each identified areas (Process optimization, Maintenance, Quality, Safety, Sustainability)

- Assessment of the required budget

- Estimated savings in the CAPEX, OPEX

- Dx investment planning for 5 years with IRR / NPV / Payback period calculations

For e.g. ROI, Pay-back period, Investment planning, Capex-Opex budget allocation

Develop Priority Matrix depending on the Digital Maturity Assessment, Availability of Assets, Process, People

- Prioritizing the Business problems based on the savings, requirements and challenges

- Identification of Dx Tech Stack(s) for implementation

- Implementation plan and risk mitigation strategy

- Change management

- Industry 4.0 training needs identification

- Cultural transformation roadmap

For e.g. Prioritisation matrix, Dx roadmap, Cultural transformation, Training

PMC for Implementation of Solution(s) – Continuous efforts for e.g., IT-OT integration, Sensor Placements, APC, APM, OTS, Digital Workforce, Others

- Develop Scalability Framework

- Implementation roll-out plan across different locations

- Continuous Improvement - Gap Analysis and Scope of Improvement – KPIs, New / Advanced Use Cases

- Evaluation of Usage of the solution implements

- Post implementation benefit analysis/ ROI calculations

- Identification of gaps in solutions that are implemented and rectification plan

- Identification of Training needs

- New Use Cases definition, New modeling framework, Advanced Analytics, etc.

PMC: Ensuring successful Dx implementation and post-implementation ROI’s

Process Optimization

With the increasing and dynamic market demands it is important to identify the opportunities for continuous improvement of the operations through real time optimization of the equipment and processes. With our deep domain expertise and process optimization know-how leverage the frameworks for improving the overall optimization strategies by making the appropriate control move to enhance the maintenance, planning and scheduling practices.

Core Expertise: Process optimization, Advanced process control (APC), Enhanced life of assets, Real time optimization (RTO), Energy optimization

Dx Tech Stacks: Imubit, Honeywell APC, Aveva, Siemens GPROMS

- Advanced process control for complex and dynamics chemical operations for autonomous operations

- Integrated PID controllers for multivariate control strategy to dynamically respond to the process changes

- Minimize process off-spec, enhanced quality control and reduced process variabilities

Techstacks:

- Honeywell Forge, Aveva APC, Aspen DMC

Deep learning process control -

(minute by minute optimization)

- Offers real time process control through complex analysis of MVs, CVs and DVs

- Integrated non-linear inferentials for real time quality control and constrained objectives / targets

- Accounting the impact of uncontrollable disturbances

- Identifies the opportunity to optimize the processes every minute within the non-linear constrained environment

Techstacks:

- Reinforcement learning

- Non-linear inferentials for quality prediction

Advanced Data Analytics

Tridiagonal Solutions bespoke solutions tailored to support the industry requirements leveraging the advanced capabilities such as digital twin, custom applications and connected analytics. Enhancing the analytics and visualization for the plant engineers and operators with improved decision making. These solutions are backed by our industry experts which helps the organizations to enable agile development at scale and better adoption through these utilities. Enhancing the current data science practise with 3D models with enhanced contextualization to enabling causalities through connected analytics using sequential modeling approach empowers the shop floor team to gain better insights from their data.

Core Expertise: Time series analytics, predictive analytics, digital twin, metadata modeling, connected analytics, smart Apps for Energy and process optimization

Dx Tech Stacks:AWS IOT Twinmaker, Azure Digital Twin, Cognite, VidyaTec, Seeq, Smart Applications

- Advanced 3D models-based visualization for the telemetry data modeling

- Integrated data management – Timeseries, SAP, MES, ERP, AIMS, and others engineering information

- Analyze the complete history of the processes and equipment

- Knowledge graphs for better information management through metadata modeling

Techstacks:

- Knowledge graphs

- Master data management

- Cognite, AWS, Azure, VidyaTec

-

- Mimic the plant conditions by connecting all the upstream and downstream equipment

- Improve the decision making through equipment level correlations and causalities

- Enhance the process and equipment reliabilities through sequential models

Techstacks:

Supervised ML techniques

Boosting and bagging methodologies

Seeq, Cognite, AWS, Azure

- Open source based tailored frameworks focused to provide the custom insights for point problems

- Applications focused to accelerate the scalability and adoption

- Built to deliver high value through physics based modeling for real time constraint modeling and optimization

Techstacks:

- Python, scipy, Tensorflow, pytorch

- Supervised and unsupervised based learning

- Fisrt principles based mechanistic modeling

- Solutions leveraging neural networks for image processing and video analytics solving complex industrial problems

- Leveraging artificial neural networks for fault detection through complex learning patterns

- Digitization of offline scanned manufacturing records through OCR

- Analyzing complex microstructures and visual quality inspection

Techstacks:

- Deep learning frameworks – Tensorflow, Pytorch - CNNs, RNNs, GAN

- Generative model, transformers - GPT-4 and others

- Improving the decision making through connected analytics for CDU operations

- Digital twin for complex refinery and petrochemical units

- Plant wide optimization

- Smart Apps for process/energy/utilities optimization for manufacturing companies

- Compressors

- Exchangers

- Steam optimization

- Energy management

- Steam and condensate balance

- Image analytics for safety measures

- Complex material microstructure pattern prediction

- Prediction of external cracks for metal casts

Process Modeling and Simulation

Tridiagonal.AI Chemical 4.0 practice leverages several technology stacks for developing the process simulators intended to enable better decision making for critical operations including startup/shutdown procedures, maintenance workflow strategies and planning and scheduling optimization. With dynamic simulators, improve the real-time process performance by understanding the dynamics through efficient and integrated visibility. Integrate the physics-based dynamic plant models mimicking the DCS controllers for effective control of critical conditions.

Core Expertise:

Time series analytics, predictive maintenance, soft-sensors, energy optimization, emission management, APM

Dx Tech Stacks:

AWS, Azure, Cognite, Seeq, Kelvin, Python, PySpark, R and others

Process Debottlenecking (Steady-state Simulation)

- P&ID mapping and process flow simulators

- Process troubleshooting and debottlenecking

- Process stabilization

- Design modification and process improvement studies

- Heat integration and pinch analysis

- Thermodynamics and process reconciliation

Techstacks: Aspen HYSYS, Honeywell UniSim, Siemens gPROMS

Dynamic Simulation (Operator Training Simulation)

- Real-time plant simulators

- Process benchmarking

- Process operators training – plant control operations

- Process improvement and benchmarking studies

Techstacks: Honeywell OTS, Yokogawa OTS, Emerson OTS, Aveva OTS

Process Optimization Simulator

- Physics-informed simulators based on deep learning networks

- Enhancing overall performance of the site to meet the cost/objective functions

- Objective-oriented models intended to optimize the economic profits

- Continuous production optimization to improve asset reliability, throughput, and energy efficiency

Techstacks: Imubit, Smart Optimizers

Virtual Reality (VR)

- 3D training and simulations using VR

- Enriched remote operations experience

- Immersive assistance in remote maintenance workflows

- Enhanced plant safety

- Enhanced productivity through efficiency and smart operations.

Agentic AI Services

Domain-Driven, Use Case- Centric, and Ready for Production

Knowledge Graph as a Service (KGaaS) is a scalable, agent-driven platform that transforms siloed, unstructured, and structured industrial data into a semantically connected, intelligent knowledge network. Built on industry standards and ontologies, the platform enables next-gen applications in root cause analysis, process optimization, SOP automation, and decision augmentation.

Knowledge Graph as a Service (KGaaS)

Powered by Agentic AI and Industry Standards | Offered by Tridiagonal.ai

Tridiagonal.ai: Industrial Intelligence Through Knowledge Graphs

Tridiagonal.ai’s Knowledge Graph as a Service (KGaaS) is a scalable, agent-driven platform that transforms siloed, unstructured, and structured industrial data into a semantically connected, intelligent knowledge network. Built on industry standards and ontologies, the platform enables next-gen applications in root cause analysis, process optimization, SOP automation, and decision augmentation.

- • Agentic AI Framework: Orchestrated agents autonomously ingest, contextualize, and reason over multi-modal data.

- • Standards-Driven Ontology: Built on ISA-95, ISO 15926, and custom domain models for chemicals, oil & gas, and discrete manufacturing.

- • Hybrid Graph Infrastructure: Supports Neo4j, Stardog, GraphDB, and Amazon Neptune for flexible, enterprise-grade deployment.

- • Industrial-AI Native: Integrates seamlessly with OSI PI, SAP PM, P&IDs, SOPs, and failure reports.

With support for hybrid deployments, standard-compliant APIs, and deep domain integration, Tridiagonal.ai ensures your transition to intelligent industrial knowledge networks is efficient, secure, and future-ready.

Overview

Our KGaaS architecture provides a full-stack framework to extract, organize, and utilize industrial data for advanced decision-making.

- 1. Ontology Creation

Domain-specific ontologies for process, asset, and reliability engineering. Includes equipment hierarchies, process flows, SOPs, work orders, RCA data, and compliance mapping. - 2. Data Ingestion Layer

Connectors for SAP PM, OSI PI, engineering documents. Uses Apache NiFi, Azure Data Factory, and NLP/DocAI agents to extract triples from unstructured data. - 3. Knowledge Graph Construction

Supports Neo4j, Stardog, GraphDB, Amazon Neptune. Uses agents for relationship resolution, deduplication, and enrichment. - 4. Querying & Reasoning Layer

Access data via SPARQL, Cypher, GraphQL. Built-in inference and validation with OWL/SHACL. Agents handle compliance checks, tag tracing, and root cause paths. - 5. Application Layer

Natural Language QA, SOP retrieval assistants, RCA tracing, and integration into dashboards (PowerBI, Grafana, custom alerting).

Use Cases Across the Asset Lifecycle

- Maintenance: Fault Tree Automation, SOP Mapping → Faster troubleshooting, SOP reuse

- Process Engineering: Root Cause Graphs, Process Deviations → Reduced downtime, better parameter tuning

- HSE & Compliance: Regulation Mapping, RCA Audit Trails → Compliance traceability

- Digital Twin: Tag and Flow Model Integration → Context-rich asset twins

- Knowledge Management: Centralized Document Intelligence → Easy access to tacit plant knowledge

Deployment & Integration Options

On-prem, hybrid, and cloud-native deployment models supported. Interfaces via REST, GraphQL, OPC UA, MQTT, OSIsoft PI, SAP OData. Built with enterprise-grade privacy, security, and version control.

Agent-as-a-Service (AaaS)

Operational Intelligence Delivered Through AI-Powered Multi-Agent Systems | Offered by Tridiagonal.ai

Tridiagonal.ai: Simulating Expert Engineers with Agentic AI

Agent-as-a-Service (AaaS) from Tridiagonal.ai transforms how industrial and process-intensive organizations approach decision-making, diagnostics, and operational planning. It combines multi-agent systems, domain-specific prompts, and cognitive frameworks to simulate the actions of expert engineers. Our agents interact with diverse data—time series, SAP, SOPs, P&IDs, simulation models—and convert them into prescriptive recommendations, anomaly detections, or planning outputs with zero hallucinations.

Agentic Frameworks for Industrial Use Cases

- Prescriptive Maintenance

- Process Investigations

- Turnaround and Shutdown Planning

- Preheat Section Energy Optimization

- Quality Deviation Investigations

- Operator Training & Scenario Analysis

- AI Lifecycle Management

- Energy & Emissions Management

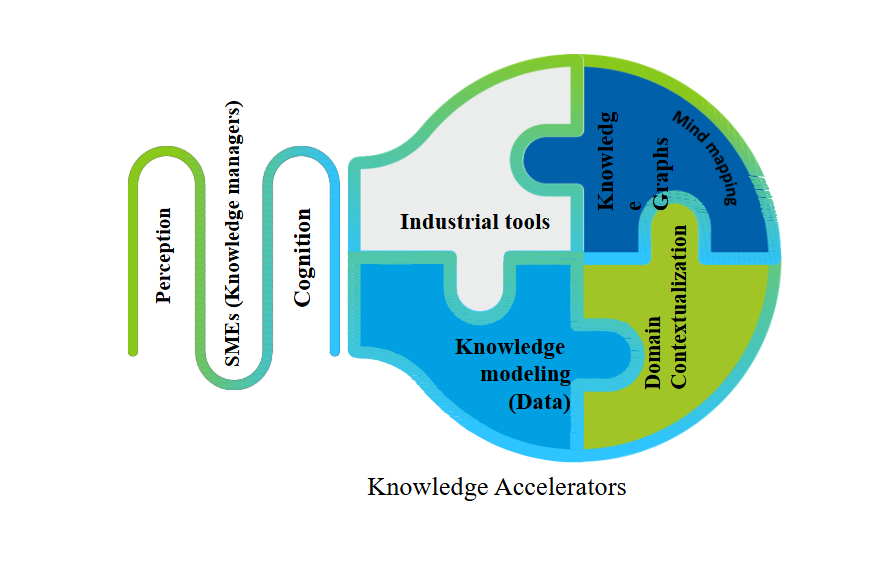

Mind Mapping Agents

A unique capability of AaaS is the use of mind mapping agents that abstract the cognitive steps followed by human experts:

- Capture cause-and-effect logic

- Build structured maps for RCA, process flow, and quality investigations

- Enable transparent, explainable decision trails for audits and compliance

Examples include:

- Maintenance RCA Agent

- Process Flow Mapping Agent

- Energy & Emissions Investigation Agent

MCP Server & Agent Orchestration

- Tool orchestration and API connectivity

- Coordination of agent tasks and handoffs

- Zero-hallucination enforcement through grounding in knowledge graphs

This orchestration ensures agents collaborate—just like a team of plant engineers—to analyze data, simulate outcomes, and recommend optimal actions.

Knowledge Graph Powered Reasoning

- Maps plant assets, systems, documents, and simulations

- Enables contextual reasoning

- Avoids fragmented answers by grounding LLMs in enterprise knowledge

We support both Neo4j and Amazon Neptune for scalable, enterprise-grade knowledge graphs.

Knowledge Accelerators

Our agents are further empowered by Knowledge Accelerators, which act as data-aware copilots for:

- SAP Agent: Interprets work orders, notifications, and equipment hierarchies

- SOPs & Manuals Agents: Extract operational logic and best practices

- Time Series Agents: Perform anomaly detection, trend analysis, and pattern discovery

- Simulation & P&ID Agents: Ground investigations in process models and schematics

Cognitive AI with First Principles Integration

- Goal-based, utility-based, and reflex-based reasoning agents

- Thoughtful prompts (zero-shot, few-shot, chain-of-thought, binary) for structured reasoning

- Seamless fusion of learned knowledge and scientific models (e.g., surge detection, isentropic efficiency, fouling calculations)

Why Agent-as-a-Service?

- Emulates expert engineer decision-making

- Speeds up diagnostics, planning, and corrective actions

- Scales across departments with specialized agents

- Modular and composable for rapid deployment

- Enables full traceability and continuous improvement

Tridiagonal.ai ensures that AaaS becomes the digital brain of your operations—smart, explainable, and always learning.

Foundation Model as a Service (FMaaS)

Empowering Enterprises with Domain-Specialized, Fine-Tuned LLMs

Tridiagonal.ai: Your Partner in Foundation Model Development

At Tridiagonal.ai, we bring deep domain expertise in manufacturing, process industries, and industrial AI to ensure your foundation models are not just powerful, but practical and aligned with real-world operations. We help customers by:

- Identifying high-impact use cases through workshops with engineering, operations, and IT teams.

- Creating labeled, contextual training datasets using decades of plant, SAP, and SOP data.

- Fine-tuning LLMs using best-fit architectures and PEFT techniques for your infrastructure.

- Building agentic frameworks that emulate SME decision-making and drive frontline productivity.

- Ensuring value delivery with post-deployment support, model monitoring, and continuous feedback loops.

With our strong partner ecosystem and proven success in complex industrial environments, Tridiagonal.ai ensures your transition to foundation model-powered intelligence is smooth, scalable, and impactful.

Overview

Our Foundation Model as a Service (FMaaS) offering enables enterprises to harness the full power of Large Language Models (LLMs) by fine-tuning them on industry-specific data and workflows. Unlike generic AI solutions, FMaaS delivers domain-optimized intelligence that understands your data, systems, and operations—resulting in highly contextual and actionable outputs.

Core Capabilities

1. Domain Accelerators

- Data Ingestion & Parsing: Extract and preprocess structured and unstructured data from SAP, SOPs, operating manuals, time series, and other sources using OCR and custom parsers.

- Domain Contextualization: Incorporate process-specific semantics, terminologies, and hierarchies into the model training pipeline.

- Templated Tokenization & Configuration: Prepare efficient training datasets using pre-built tokenization templates and configuration standards.

- Training Pipeline (PEFT): Utilize Parameter-Efficient Fine-Tuning techniques like LoRA and QLoRA to reduce cost and optimize model performance with minimal GPU load.

2. Model Fine-Tuning

We support fine-tuning on top open-source foundation models such as:

- LLaMA 3 (Meta): Multi-purpose LLMs with large context windows.

- Mistral 7B / Mixtral: High-performance models optimized for latency-sensitive workloads.

- Falcon 40B: Suitable for document summarization and generative tasks.

Our infrastructure supports models trained on 2× A100 or 1× H100 GPUs, with flexible deployment on-prem or in the cloud.

3. LLM Deployment & Evaluation

- Evaluated on domain-specific benchmarks.

- Deployed via secure APIs for integration with enterprise systems.

- Connected to vector databases for semantic search and retrieval.

- Continuously improved through user feedback and system learning loops.

4. Model Inferencing & Application Delivery

- RAG/KAG Pipelines: Combine retrieval-augmented generation with knowledge graphs to deliver grounded, reliable responses.

- Knowledge Graph Delivery: Use ontologies to interlink enterprise knowledge for real-time decision support.

- Agentic AI Frameworks: Deploy task-specific agents that simulate expert decision-making using the foundation model backbone.

- Final Applications: Build custom workflows such as smart document assistants, process troubleshooting bots, or predictive advisory agents.

Recommended Infrastructure

- GPU: ≥ 1× A100 / H100 / RTX 4090

- CPU: ≥ 16 cores

- RAM: ≥ 128 GB

- Storage: ≥ 1TB NVMe SSD

- OS: Ubuntu 20.04 or 22.04

LLM Ecosystem & Capabilities

We collaborate with leading AI and infrastructure providers, including:

- NVIDIA

- DELL

- HuggingFace

- Mistral AI

- Meta

- Claude

- DeepSeek

- Neo4j

- AI21 Labs

—ensuring compatibility, performance, and innovation.

Why FMaaS?

- Built for enterprises with complex workflows

- Delivers contextualized AI for real-world decision-making

- Reduces deployment cost with efficient fine-tuning (PEFT)

- Enables ongoing learning and adaptation through user feedback

Tridiagonal.ai — Pioneers of AgentOps in Process Industry

World’s First Agentic AI Platform for Industrial Reasoning, Decision-Making & Execution

What is AgentOps?

AgentOps by Tridiagonal.ai is the first-of-its-kind industrial solution enabling human-like cognitive agents to autonomously analyze plant data, perform reasoning, and trigger actions. Think of it as your Digital Engineering Workforce — powered by AI agents that mimic domain experts in process engineering, maintenance, operations, and troubleshooting.

These multi-agent systems go far beyond traditional ML by combining:

- Data + Knowledge + Context + Goals

- Industrial physics + domain heuristics + generative knowledge

AgentOps isn't just AI — it’s AI that acts, thinks, and collaborates.

Agentic AI System: How It Works

Tridiagonal.ai’s AgentOps system is built on a multi-layered orchestration of AI agents:

- 🔹 Orchestrator Agent

Coordinates tasks between sub-agents based on goals, prompts, and event triggers. - 🔹 Specialized Agents

Each expert agent handles a specific cognitive task — from SOP retrieval to RCA to scenario simulation:- Fault Analysis Agent

- Process Optimization Agent

- SOP Compliance Agent

- Simulation/Prediction Agent

- Knowledge Query Agent

- 🔹 KAG (Knowledge Augmented Generation) Core

Multimodal LLM infused with:- Generative prompts (tree of thoughts, CoT, binary paths)

- Domain constraints

- 1st principle logic

- ML + physics-based reasoning

Integration with Industrial Intelligence

AgentOps connects with your plant data ecosystem — enabling context-rich decision-making:

| Data Source | Integrated Examples |

|---|---|

| Time Series | OSI PI, SCADA, DCS |

| SAP | Maintenance orders, asset hierarchy, notifications |

| P&IDs | PDF/DWG parsing, tag mapping, equipment zoning |

| Manuals & SOPs | SOP step extraction, compliance modeling |

| 3rd Party Models | Simulation outputs, digital twin, advanced analytics |

Real-World Applications

- CDU Preheat Section Optimization

- Compressor Predictive Maintenance

- What-If Process Scenario Analysis

- Energy Management

- Maintenance Workflow Automation

- Quality Deviation Root Cause Analysis (RCA)

These applications are agent-triggered, context-aware, and continuously learning.

Knowledge Accelerators Embedded

- AI/ML lifecycle agents

- Vibration & oil analysis interpreters

- Fouling, surge, or trip condition detectors

- SOP violation detectors

- What-if simulators and prescriptive planners

Industrial Tools Compatibility

- AspenTech, Honeywell, Siemens

- SAP PM/ECC/S4

- OSI PI, Ignition

- Azure/AWS Data Lakes

- Neo4j, Stardog, Amazon Neptune

-1.webp)

Industries

Industry domain know - how with technology (digital) expertise.

Oil & Gas

01We provide end-to-end digital solutions for Oil and Gas and alternate energy. Our team consists of process engineers who have industry/operations experience of process optimization, maintenance and sustainability.

Areas: Advanced process analytics (predictive/ prescriptive), Advanced process control (APC), Real-time optimization (RTO), AI-based process control, Energy optimization, Digital twin, Operator training simulation (OTS), Generative AI, etc.

Life Sciences/Pharma

02We have been working with fortune 100, 500 life science and pharma companies from last 16+ years. Our core expertise includes process development and scale-up & tech transfer, manufacturing intelligence, energy optimization, etc.

Areas: Golden batch analytics, Bioreactor hybrid modeling, Batch-to-batch analysis, Predictive maintenance, product quality prediction, OEE, NLP, Gen-AI for COA.

Metals, Mining & Cement

03Our metals, mining and cement practice deals with process optimization, energy efficiency and predictive maintenance of critical units/ processes. We support customers right from setting up industry data ops/ data fabric to predictive analytics, digital twin, AI-based process control.

Areas: Smelter digital twin, Furnace optimization, Kiln optimization, Sintering plant, ID fan, Mills, OEE, etc.

Food, Beverages & CPG

04We cater to safe and sustainable operation of F&B customers using Industry 4.0 tech stacks. The major focus is on quality, production increase, waste reduction, energy efficiency, inventory reduction, operating cost reduction.

Areas: OEE, product deviation monitoring, batch cycle time, product quality prediction, Equipment run length optimization, Gen AI, etc.

Chemicals & Petrochemicals

05Our focus in chemical industry is majorly on conversion units such as distillation columns, reactors, steam optimization, etc. The end objective is to enhance operational efficiency, agility, and sustainability.

Areas: Predictive quality (soft sensors), Advanced process control for columns, Predictive maintenance of critical assets (heat exchangers / condensers, compressors, etc.)

Power & Renewables

06We have experience in deploying solutions for power generation, transportation and distribution. The focus is in improving asset reliability and prevent unplanned shutdowns. forecasting environmental conditions that impact energy production, etc.

Areas: Coal blend quality prediction, Turbines and boiler energy optimization, Predictive maintenance of ID fans, Emissions modeling, Cooling tower make-up water optimization.

Practice Heads

Mr. Praveen Kapse is Tridiagonal AI's Vice President – Global Strategy and Technology. He is leading the Manufacturing Excellence and Digital Transformation group as well. He has more than 23 years of experience working in the Technology domain across different industry verticals. His core competence involves conceiving strategies for successfully introducing new technologies and solutions, such as Industry 4.0 in the process manufacturing space. With a strong techno-commercial background, he has been implementing large digital transformation programs for various companies across the globe.

Sandeep Kulkarni holds a Bachelor's degree in Mechanical Engineering with a specialization in Production Engineering and has completed advanced computing studies at CDAC. With over 28 years of extensive experience in operational excellence within the refinery, petrochemical, and chemical industries, he is a seasoned professional. His expertise spans process automation, end-to-end value chain integration, and digital transformation, including Industry 4.0 initiatives. Sandeep has led numerous projects for major clients such as Singapore Refinery, Petronas, ExxonMobil, Chevron, TOTAL, Shell, KOC, and Pertamina.

He leads a business unit of 100 engineering professionals, delivering state-of-the-art engineering services to global process industries through technology partners such as Honeywell, Emerson, Aveva, and Yokogawa. Sandeep has been instrumental in developing a collaborative engineering services ecosystem to support the digital transformation journey of process industry clients.

Parthprasoon Sinha, Masters in chemical engineering with diverse cross industry experience supporting physics based data driven solutions. While leading the data science group in Tridiagonal solutions, has crafted several scalable data driven solutions for various initiatives. Has expertise in delivering projects focused on - predictive maintenance, energy management, process optimization and Gen AI.

Has delivered more than 50 projects globally, >50 Digital transformation workshops and others. Has capacity of delivering the bespoke solutions over multiple platforms - Cognite, Seeq, Kelvin, Databricks, AWS, Azure, Litmus Edge and others.

Kedar Vechalekar brings over a decade of invaluable experience to his role as Delivery Head accomplished professional with a prestigious Master's in Technology from IIT Bombay, Kedar also holds a Bachelor's degree from Pune University, where he was honored with a Gold Medal. He is PMP certified and possesses extensive expertise in research, operator training simulators, dynamic and steady state simulations. Kedar has successfully delivered over 40 high-impact projects across the oil and gas, petrochemicals, polymers, green hydrogen, and fertilizer industries. Renowned for his leadership and precision, he excels in guiding teams to ensure the seamless delivery of complex projects. Kedar specializes in implementing cutting-edge technologies such as Gen AI to optimize time and effort for traditional tasks. His profound expertise and unwavering dedication drive the success and innovation at our company.

-1.jpeg?width=503&height=475&name=Media%20(2)-1.jpeg)

A Chemical Engineer with 15+ years of extensive experience in Project management, refinery operations across multiple process units. Currently serving as a -- for the Oil & Gas vertical which involves data driven process optimization projects, AI based optimization, providing advanced technological solutions such as Gen AI, Agentic-AI, etc. Strong expertise in unit operations, turnaround management, project execution, and reliability improvement in the petroleum refining industry. Successfully led teams for refinery capacity expansion projects and implementation of digital transformation initiatives. Proficient in process optimization, troubleshooting, and energy management for operational excellence.

Skilled in identifying and implementing cost optimization strategies and reliability enhancement projects to ensure profitability and operational stability.

Why Tridiagonal.AI?

Resources

Explore the best practices and success stories of applying technology in the process industry.

Curious about how our Generative AI can streamline your operations?

Prebuilt and Configurable AI Agents for Manufacturing Operations

Easy to Use. Fast to Deploy. Built to Accelerate Your Operational GPT.