Transforming Refinery Complexity into clarity

Vertical AI for Oil, Gas & Energy

Industry Overview

High energy intensity from fired heaters, boilers, and steam systems

Crude and yield variability across CDU, FCC, and HCU units

Emissions compliance tightening every year

Costly downtime from compressors, exchangers, SMR/PSA failures

Disconnected decision layers across APC, RTO, optimizers, and ML models

What is AI PlantOps?

AI Plant Ops

Clusters & High-Impact Use Cases

Crude blending

In the oil & gas world, it usually refers to the practice of mixing different grades of crude oil to achieve a target quality—say, adjusting sulfur content, viscosity, or API gravity—so the final blend meets refinery requirements or market specs. Refineries often do this to optimize processing costs and product yields.

In a general sense, “crude blending” could just mean any rough or unrefined mixing—like combining things without much precision.

CDU Cut-point optimization

CDU = Crude Distillation Unit.

When we talk about cut-point optimization, we’re essentially talking about where we decide to “cut” between different product streams in the distillation column.

In a CDU, crude oil is separated into fractions like naphtha, kerosene, diesel, gas oil, residue, etc. Each fraction has a boiling range. The “cut point” is the temperature (or boiling range boundary) where one product ends and the next begins.

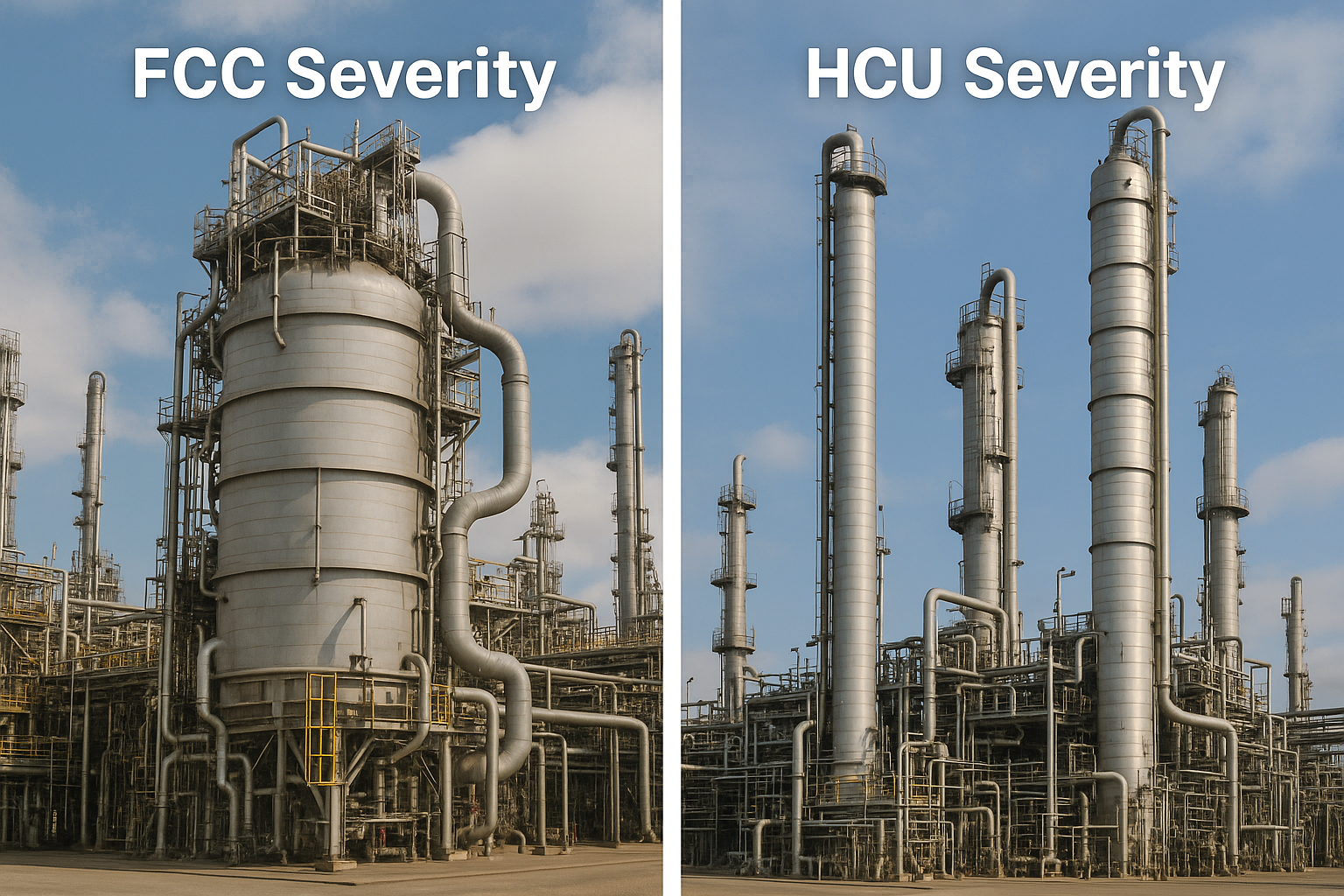

FCC/HCU severity

When we talk about FCC (Fluid Catalytic Cracking) or HCU (Hydrocracking Unit) severity, we’re basically talking about how “hard” we run the unit — the operating intensity that drives how much cracking, conversion, or upgrading actually happens.

-

In FCC → severity is tied to reactor temperature, catalyst-to-oil ratio, and contact time. Higher severity = more gasoline and LPG, less heavy cycle oil, but also more coke and dry gas.

Catalyst

Catalyst: A catalyst is a substance that speeds up a chemical reaction without being consumed in the process. In refining, catalysts are crucial in conversion units such as FCC, hydrocracking, reforming, and hydrotreating. They enable reactions like cracking, hydrogenation, desulfurization, and reforming to occur at lower temperatures and pressures than would otherwise be required, improving efficiency and selectivity.

Hydrogen Management

Hydrogen management is one of those refinery topics that looks boring on paper but is actually the lifeline of the whole downstream business .

Here’s the plain truth: hydrogen is like oxygen for a refinery—without it, all the upgrading units choke.

Why hydrogen matters?

-

Desulfurization (HDS): Stripping sulfur out of fuels (for clean diesel, gasoline, jet fuel) eats hydrogen.

Purity

Purity in Process Industries: In process industries such as oil refining, petrochemicals, pharmaceuticals, and food processing, purity refers to the extent to which a material or product is free from contaminants, by-products, or undesired compounds. Maintaining high purity is essential because even small amounts of impurities can damage catalysts, reduce process efficiency, or cause a product to fail quality specifications.

Routing

Routing in Process Industries: Routing refers to the planned path or sequence through which raw materials, intermediates, or finished products flow within a plant or system. In manufacturing and refining, routing determines how feedstocks move across equipment, pipelines, and processing units to achieve the desired conversion or treatment. For example, in a refinery, crude oil may be routed first to the CDU, then specific fractions are routed to units like FCC, hydrocracker, or reformer depending on product requirements.

SMR/PSA recovery efficiency

SMR/PSA Recovery Efficiency: In refineries and chemical plants, hydrogen is often produced by Steam Methane Reforming (SMR), where natural gas reacts with steam over a catalyst to generate a hydrogen-rich syngas. Since this gas also contains CO, CO₂, and methane, a Pressure Swing Adsorption (PSA) unit is used to separate and purify the hydrogen.

Fuel Mix

The term fuel mix refers to the distribution of different energy sources—such as coal, natural gas, hydro, solar, wind, or nuclear—used in power generation, which serves as critical input data for modeling and analysis. AI/ML algorithms can analyze historical fuel mix patterns, detect hidden correlations with demand, price fluctuations, and carbon emissions, and generate forecasts of future energy shares under different scenarios.

Steam/power

In the energy sector, steam power refers to the generation of electricity using steam produced from heating water, typically by burning coal, natural gas, or through nuclear reactions. The steam drives turbines, which in turn generate power. From a data science and AI/ML perspective, steam power data becomes valuable for analyzing plant efficiency, fuel consumption, and emission patterns.

Flare minimization

Flare minimization refers to reducing the routine or continuous burning of hydrocarbons through the flare system in refineries, petrochemical plants, and gas processing units. The flare is essentially a safety device—an outlet to burn off excess gases during process upsets, startups, shutdowns, or emergencies. But if a plant flares too much under normal operation, that’s wasteful and costly.

.png)

Integrated production planning

Integrated Production Planning (IPP) is basically the backbone of how modern industries run their operations without chaos. Instead of handling procurement, manufacturing, inventory, and distribution in silos, IPP ties everything together into a single coordinated system.

Think of it as making sure raw materials, machines, labor, and customer demand are aligned so production flows smoothly, without bottlenecks or overstock. It’s not just about scheduling what to make and when—it’s about synchronizing the entire supply chain.

Emissions Monitoring

Emissions Monitoring is the practice of continuously tracking and analyzing the gases and particulates released during industrial operations to ensure compliance with environmental standards and to optimize sustainability goals. In modern AI/ML-driven systems, emissions monitoring isn’t just about collecting data from stacks, vents, or processes—it’s about turning that data into actionable insights.

.gif)

PlantGPT Assistant

PlantGPT Assistant is an AI-powered digital assistant built for modern plants and factories. It leverages natural language processing, machine learning, and knowledge graphs to understand operational data and provide context-aware insights. Instead of digging through dashboards, reports, or manuals, operators can simply ask PlantGPT questions like:

-

“What’s the cause of the efficiency drop in Line 3?”

-

“How are today’s emissions compared to last week?”

.png)

Predictive Degradation

How it works in practice:

-

Data capture

-

Degradation modeling

-

Remaining Useful Life (RUL)

-

Proactive maintenance

-

Integration with plant systems

Risk Based Prioritization

How it works in an industrial + AI/ML context:

-

Risk assessment

-

Data-driven ranking

-

Prioritized action plan

-

Dynamic adjustment

-

Business alignment

Why It Matters

Reduce energy cost & emissions intensity

Increase yields & margins through cross-unit coordination

Cut unplanned downtime via predictive reliability safeguards

Realize more value from existing APC, RTO, and optimizers

Enable explainable, automated decision-making at scale