What is DomainWise – Your Gateway to PlantGPT?

To meet the advisory needs of the manufacturing operations, we introduce PlantGPT, powered by our DomainWise is a next-generation solution that fuses knowledge contextualization, deep domain expertise, and an operations-centric multi-agent framework.

It is built around purpose-designed micro-agents that collaborate to provide real-time conversational assistance, decision support, and advisory insights tailored to daily plant operations.

Each micro-agent is specialized to contextualize information, interpret operational data, and deliver actionable knowledge precisely when and where it’s needed.

By orchestrating these intelligent agents, the DomainWise bridges the gap between raw operational data and expert decision-making, enhancing situational awareness, operational efficiency, and plant reliability.

DomainWise PlantGPT Features

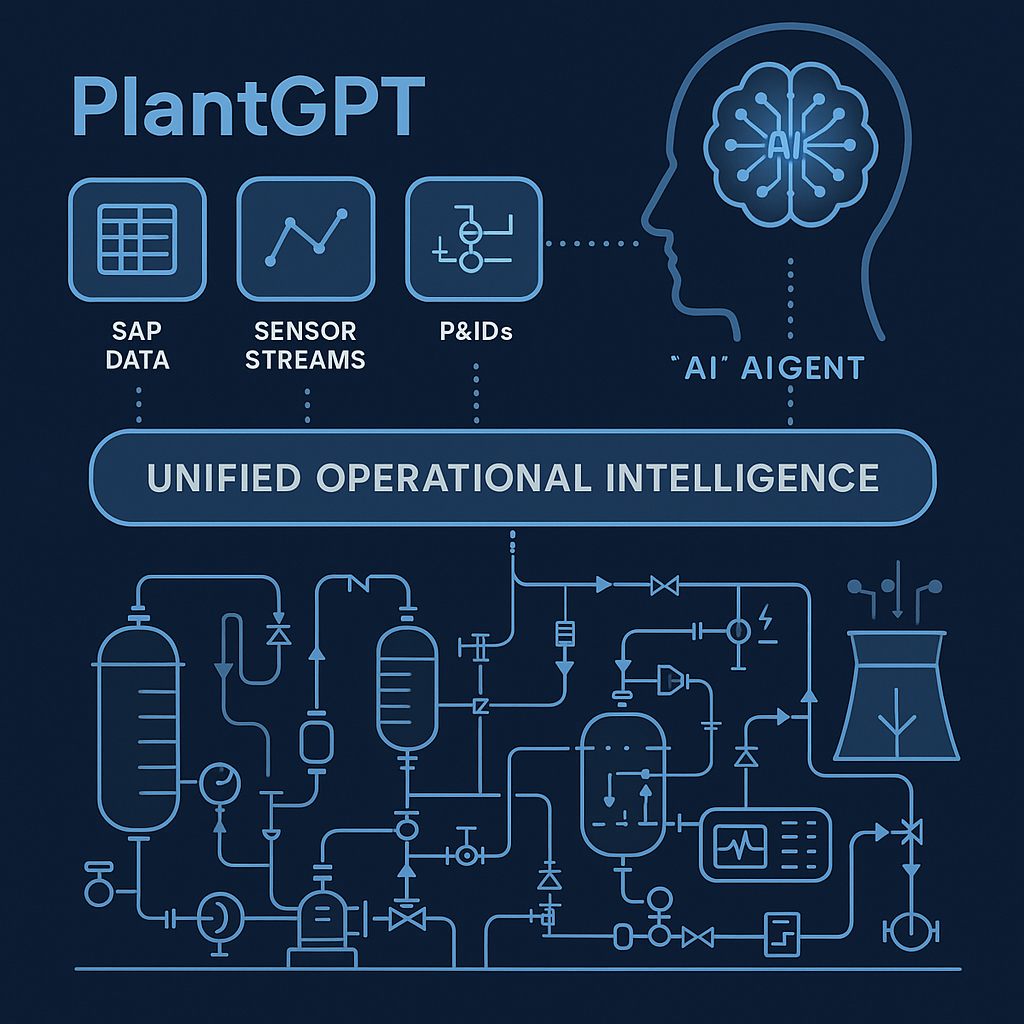

Intelligent Perception & Contextual Data Mastery

PlantGPT transforms fragmented industrial data into unified operational intelligence. By seamlessly contextualizing SAP data, sensor streams, P&IDs, and maintenance logs, PlantGPT empowers AI agents to perceive complex plant systems holistically. This deep perception provides the foundation for proactive decision-making, optimized processes, and smarter plant operations.

Knowledge Data Modeling with SME-Infused Cognition

PlantGPT captures and structures domain expertise through SME-guided knowledge modeling. By embedding human insights directly into foundational data models, PlantGPT ensures AI agents interpret operational data with the expertise of seasoned engineers. This fusion of data and cognition enables intelligent, plant-specific decisions that enhance accuracy, speed, and reliability across workflows.

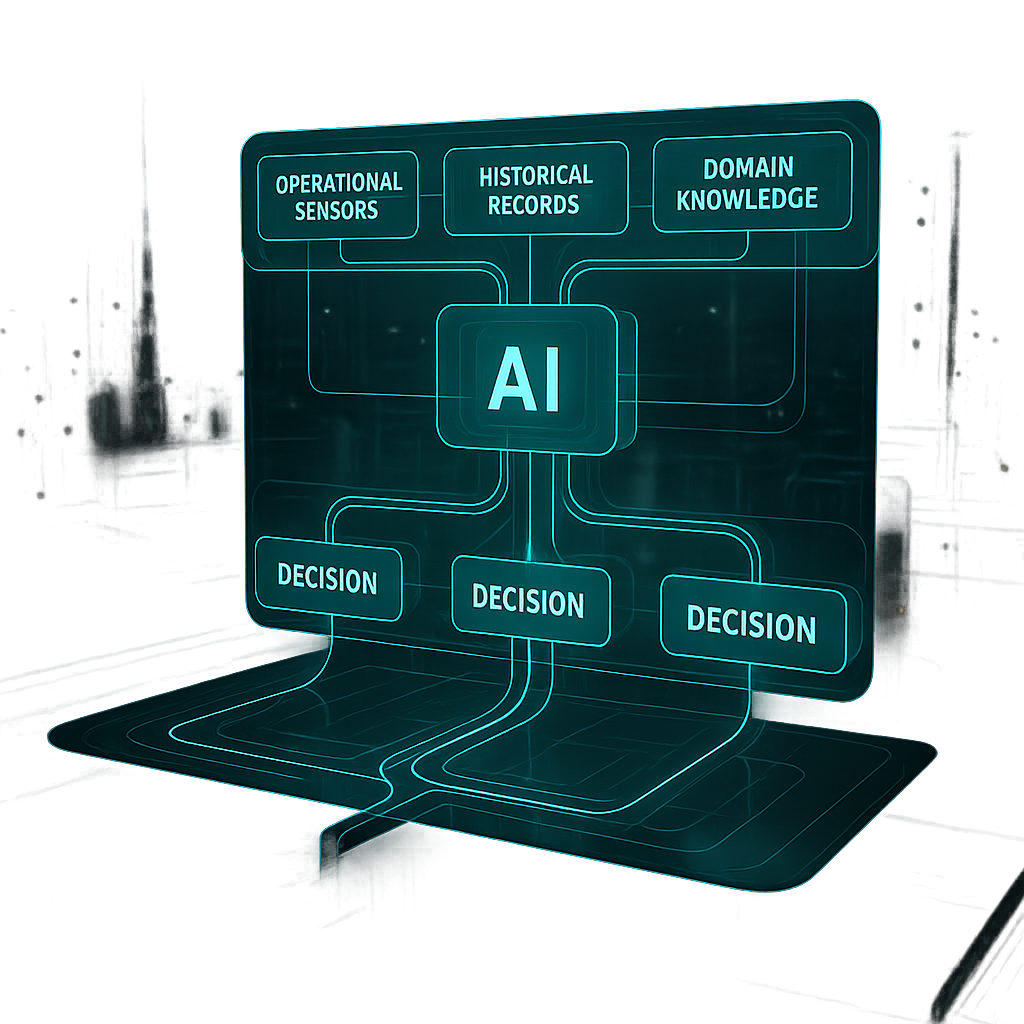

Decision Graphs: Transparent Pathways to Intelligent Action

PlantGPT engineers transparent decision-making through dynamic Knowledge Graphs. These graphs map how operational data, historical context, and domain knowledge converge to drive AI actions. Plant teams can trace every recommendation back to its source, ensuring explainable, auditable, and trustworthy AI-driven decisions throughout plant operations.

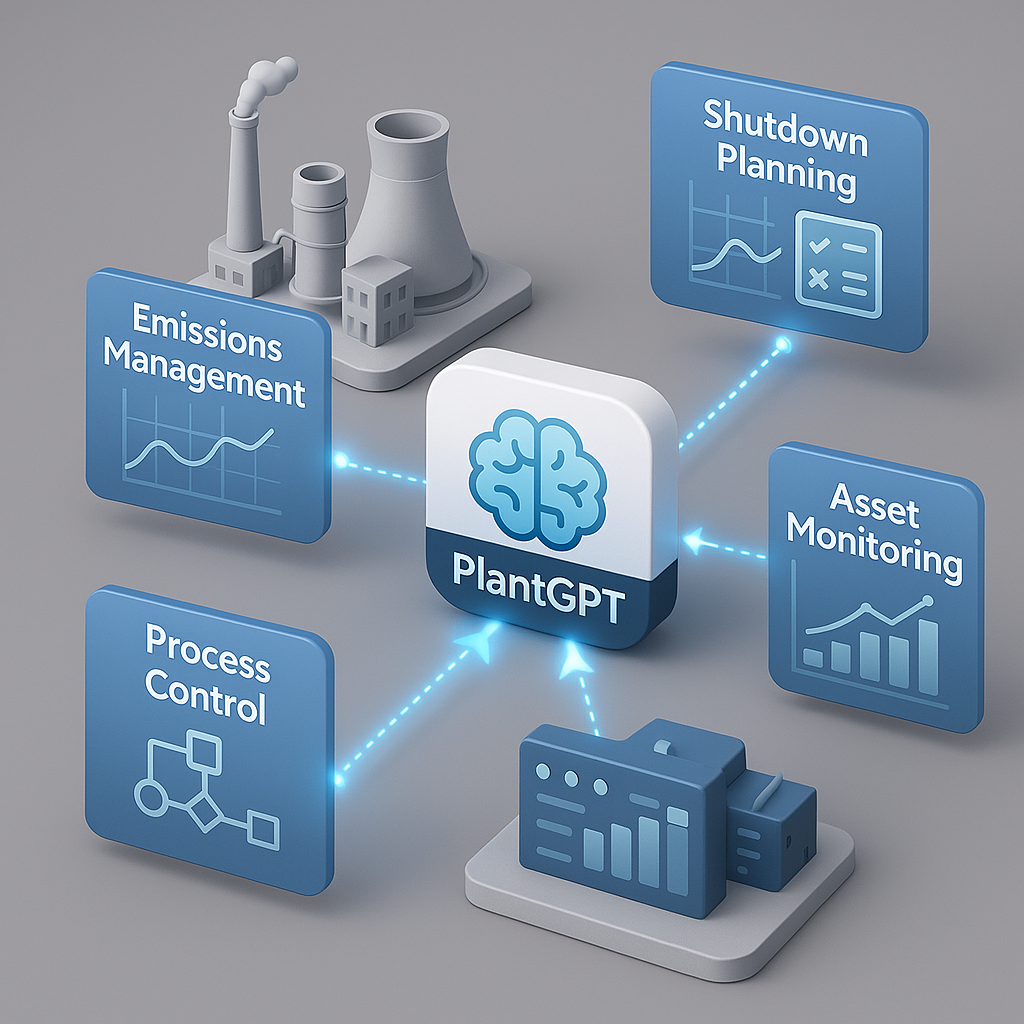

Workflow-Level AI Automation for Industrial Operations

PlantGPT embeds AI-driven intelligence directly into operational workflows, ranging from emissions management to shutdown planning. AI agents orchestrate actions across processes, enabling faster decision cycles, improved asset reliability, and optimized resource utilization. With PlantGPT, plants evolve beyond isolated analytics toward truly intelligent, autonomous, and integrated operations.

Hybrid Agentic Intelligence: Traditional AI Meets LLM Power

PlantGPT combines traditional machine learning with LLM-powered contextual reasoning to create a hybrid intelligence ecosystem. Predictive models provide foresight, while agentic LLMs reason about operational impacts and recommend next steps. This dual-engine architecture ensures plants achieve actionable, context-aware, and agile decision-making at industrial scale.

Knowledge Management: The Industrial Brain for AI-Driven Operations

PlantGPT builds a living, dynamic knowledge fabric by digitizing and contextualizing enterprise knowledge. AI agents continuously access and activate this structured plant memory to deliver real-time insights, ensure operational consistency, and accelerate excellence. By transforming passive information into an intelligent, evolving resource, PlantGPT powers AI-driven plant operations with unmatched agility and precision.

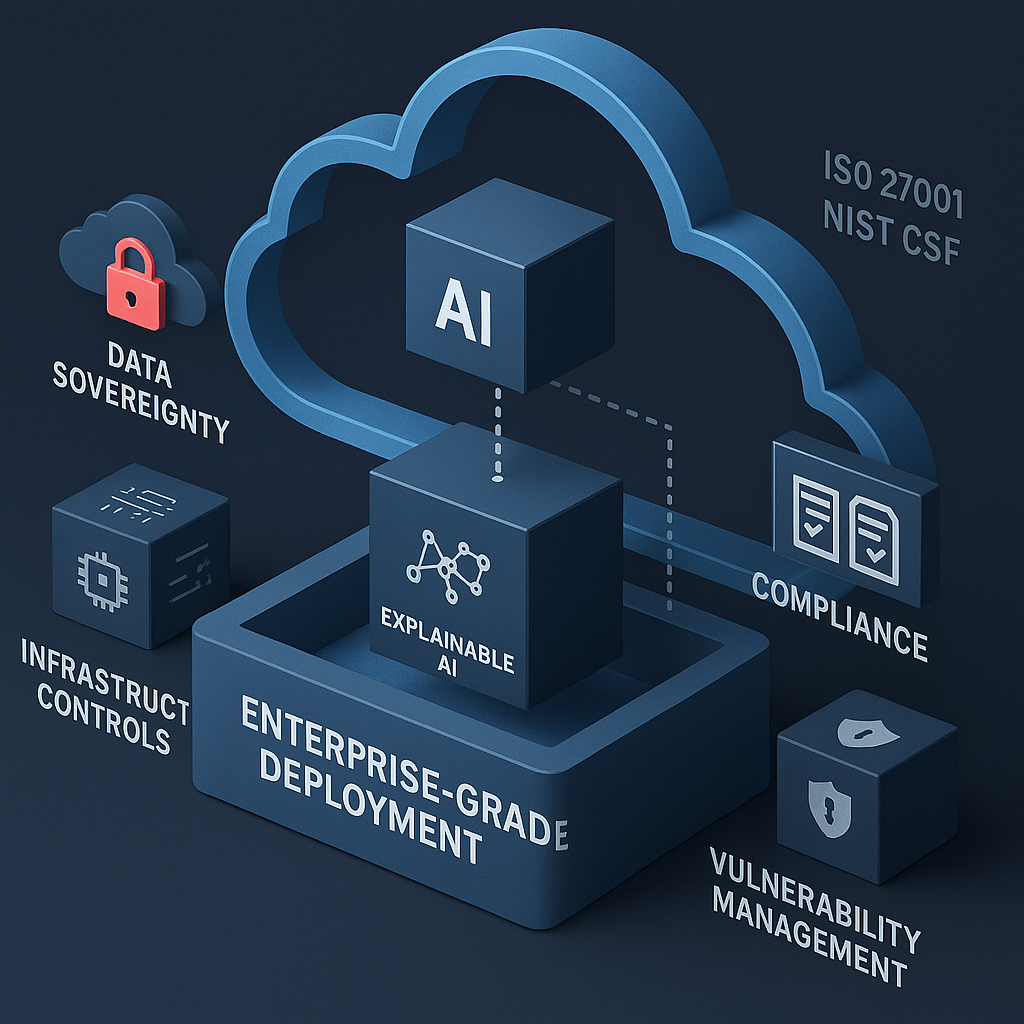

Built for Trust & Control

- Secure, Enterprise-Grade Deployment

- Your Cloud, Your Control: Fully deployed within your cloud tenant, ensuring zero external data sharing.

- Data Sovereignty: Compliant with legal, regulatory, and data residency requirements across jurisdictions.

- Enterprise-Grade Protection: Incorporates infrastructure controls and robust security measures to safeguard your data.

- AI & Model Security

- Isolated Deployment: AI models operate entirely within your infrastructure, eliminating exposure risks.

- Private & Ownable: Models are fine-tuned for your use case with full intellectual property ownership.

- Explainable AI: Decision-making is transparent and traceable via graph-driven analytics.

- Compliance & Governance

- Standards-Driven: Designed to support frameworks such as ISO 27001, NIST CSF, and operational technology (OT) compliance.

- Custom Policy Support: Tailors to your enterprise’s governance requirements and internal policies.

- Threat Resilience: Includes built-in vulnerability management to maintain system integrity.

Agentic AI Applications in Manufacturing Operations

Agentic AI for Maintenance Management

Real-time Insights to Action – Minimize Downtime

-2.png)

Root Cause Analytics (RCA)

WORKFLOWS

- Deviation alerts in real time

- AI-based fault tracing

- Prescriptive recommendations

- Faster root cause identification

- Self-learning agent models

-4.png)

Maintenance Planning

WORKFLOWS

- Dynamic scheduling

- Task automation

- Asset prioritization

- AI plans tasks by risk & health

- Proactive issue forecasting

-3.png)

Turnaround & Shutdown

WORKFLOWS

- Scope optimization

- Real-time scheduling

- Cost-risk balancing

- Adapts plans to evolving data

- Reduces delays & overruns

-4.png)

Rotating Asset Lifecycle

WORKFLOWS

- Live model monitoring

- Drift detection

- RCA integration

- Ensures performance reliability

- Supports remote diagnostics

Agentic AI for Quality Excellence

Proactive, Predictive, and Intelligent Quality Management

Quality RCA

WORKFLOWS

- Detects quality deviations early

- Auto RCA using production data

- Recommends quick fixes

- Accelerates resolution cycles

- Learns from past issues

.png)

Quality Management

WORKFLOWS

- Real-time process monitoring

- Predictive alerts on deviations

- Suggests context-aware actions

- Enables proactive control

- Drives agile quality ops

-1.png)

Complaint Investigation (CAPA)

WORKFLOWS

- Auto triage of complaints

- Fast root cause tracing

- CAPA suggestions on the fly

- Reduces repeat issues

- Enables continuous learning

Agentic AI for Process Excellence

Faster Insights, Smarter Actions, Sustainable Performance

-1.png)

Process Investigation and Root Cause Analysis

WORKFLOWS

- Real-time process deviation detection

- Automated root cause identification

- Prescriptive corrective actions

- Continuous learning for refined models

What-If Analysis / Scenario Planning

WORKFLOWS- Real-time scenario simulation

- Risk and impact assessment

- Prescriptive operational strategies

- Agile decision support for quick adjustments

-1.png)

Refinery CDU Pre-Heat Optimization

WORKFLOWS- Monitors heat exchanger performance

- Dynamic cleaning recommendations

- Pre-heat network optimization

- Energy and cost savings

-2.png)

APC/RTO/Optimizer Lifecycle Management

WORKFLOWS- Continuous monitoring of APC/RTO systems

- Real-time detection of performance degradation

- Prescriptive root cause analysis and corrective actions

- Optimization aligned with plant conditions

-3.png)

LifeScience's CIP/SIP Optimization

WORKFLOWS- Monitors CIP/SIP operations

- Suggests cycle adjustments for efficiency

- Supports cleaning validation for compliance

- Reduces resource usage and downtime

.png)

OEE (Overall Equipment Effectiveness) Optimization

WORKFLOWS- Tracks asset availability, performance, and quality losses

- Detects micro-stoppages and defects

- Recommends actions to improve OEE

Agentic AI for Sustainability — Energy & Emissions Management

Optimizing Operations for Sustainability

-1.png)

Energy Efficiency Optimization

WORKFLOWS

- Reduces energy waste and improves efficiency.

- Monitors consumption to optimize usage.

-2.png)

Renewable Energy Integration

WORKFLOWS- Integrates renewable sources into operations.

- Improves energy resilience with cleaner energy.

-3.png)

Emissions Tracking

WORKFLOWS- Monitors emissions and identifies hotspots.

- Supports regulatory compliance and reporting.

-4.png)

Smart Grid Management

WORKFLOWS- Optimizes energy flow and storage.

- Balances renewable and non-renewable energy sources.