How It Works?

AIML Agent uses Agentic AI and Generative AI to orchestrate the entire AI/ML model lifecycle intelligently — ensuring sustained performance, regulatory alignment, and operational impact.

-

Step 1Intelligent Contextualization of Preheat Data

-

Step 2Continuous Monitoring and Deviation Detection

-

Step 3Dynamic Analysis and Predictive Forecasting

-

Step 4Prescriptive Optimization Recommendations

-

Step 5Smart Maintenance Planning and Reporting

.gif?width=800&height=530&name=2990_Tridiagonal-Solutions_giff1_Aug24-2%20(1).gif)

- Dynamic Knowledge Graphs: Agentic AI unifies time series, PFDs, P&IDs, exchanger design data, and maintenance histories into a living plant knowledge map.

- Operational Linkage: AI connects exchanger health, performance data, and process variations to reveal hidden interdependencies.

- Performance Degradation Alerts: Agentic AI continuously monitors exchanger parameters (e.g., U-values, fouling indices) to detect efficiency loss early.

- Real-Time Deviation Signals: AI flags abnormal thermal load distributions and alerts maintenance teams proactively.

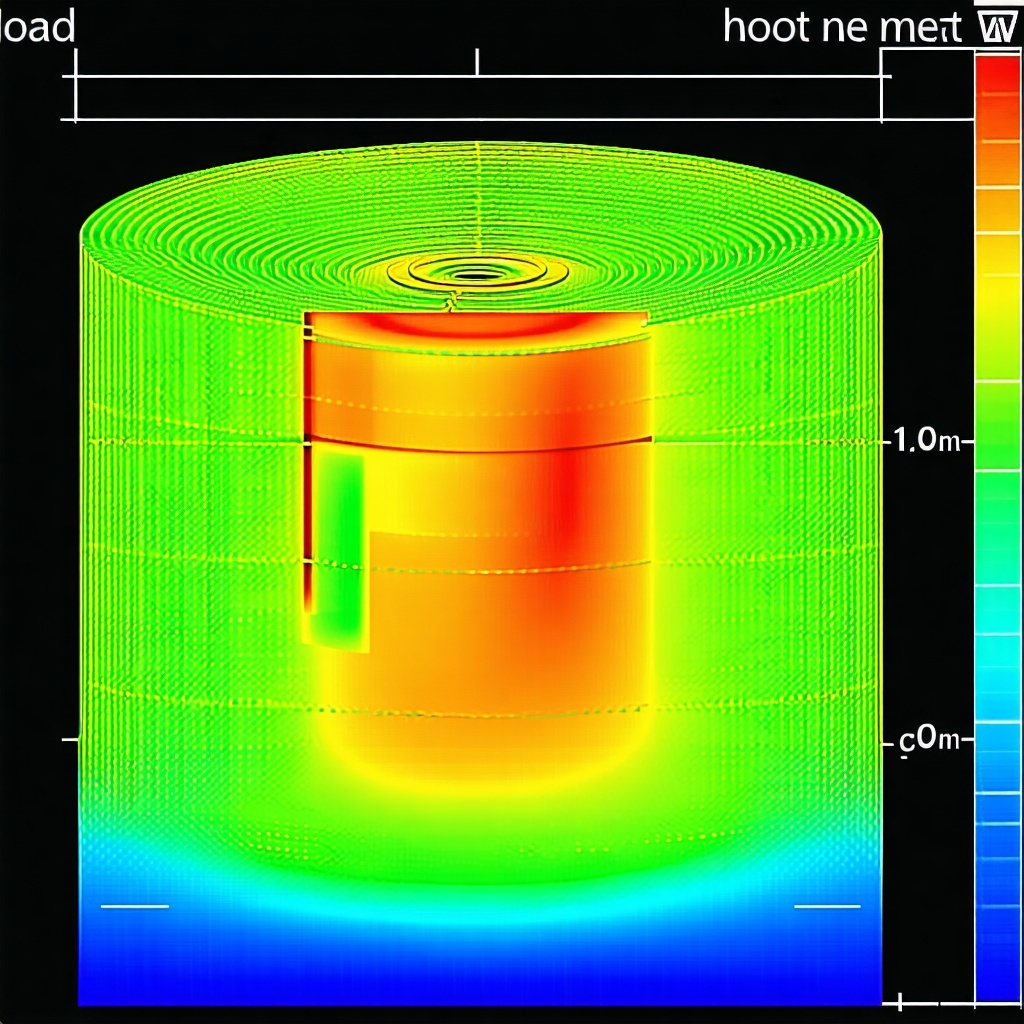

- Live Heat Distribution Modeling: Generative AI adjusts thermal load balancing across exchangers based on feedstock changes and temperature fluctuations.

- Predictive Maintenance Forecasts: Agentic AI predicts end-of-cycle timing, exchanger failures, and maintenance needs dynamically.

- Operational Strategy Suggestions: AI recommends optimal flow adjustments, exchanger cleaning schedules, or bypass strategies to maximize train performance.

- Impact-Feasibility Decisioning: Agentic AI ranks interventions by operational benefit, energy efficiency gains, and risk mitigation.

Inspection Rounds

- Maintenance Prioritization: AI generates maintenance action plans based on predicted degradation risks, minimizing unnecessary shutdowns.

- Audit-Ready Insights: Agentic AI structures exchanger health reports, maintenance justifications, and operational optimization logs automatically.

Industries we are transforming with Gen-AI, based on Tridiagonal HexAgent

Technology Behind the Transformation

Tridiagonal HexAgent Features

Tridiagonal HexAgent empowers your business with a suite of advaced features designed to streamline operations and drive growth.

Comprehensive Preheat System Mapping

01Agentic AI fuses design, operational, and maintenance data into dynamic knowledge graphs for full system visibility.

Predictive Degradation Detection

02AI agents monitor exchanger health indicators in real time, detecting performance degradation 30–40% faster than manual tracking.

Dynamic Heat Load Optimization

03Generative AI models adjust thermal load distribution dynamically, improving heat recovery efficiency by 5–10%.

Prescriptive Maintenance Recommendations

04Agentic AI prescribes optimal maintenance timing and cleaning strategies, reducing exchanger downtime by 15–25%.

Early Warning System for Critical Failures

05Continuous monitoring triggers early alerts, minimizing the risk of sudden exchanger outages and unplanned shutdowns.

Maintenance and Operations Alignment

06HexAgent intelligently balances operational targets (efficiency, energy use) with maintenance planning for better resource allocation.

Energy Efficiency and Emissions Impact

07Optimized heat exchanger operation improves plant energy efficiency, potentially reducing overall fuel consumption by 5–8%.

About Us

Tridiagonal AI Pvt. Ltd. (TSPL), Digital Transformation in Process Manufacturing is a premier Industry 4.0 consultant specializing in Manufacturing Excellence and Digital Transformation. We are an end-to-end execution partner for Chemical 4.0 programs, offering expertise in IT-OT integration, advanced data analytics, energy optimization, and Generative AI. Our capabilities span Digital Transformation Consulting, Process Data Analytics, Process Optimization, and more. From strategy to implementation and ongoing support, we ensure the success of your digital initiatives. Partner with us to unlock the full potential of your digital investments and drive transformative change in your operations.

Detection of Exchanger Performance Degradation

Faster

Heat Recovery Efficiency

Improvement

Unplanned Downtime

Reduction

Manual Data Analysis Efforts

Reduction

Overall Plant Fuel Consumption

Reduction

Better Maintenance and Resource Planning

Regulatory Compliance and Reporting Readiness

Faster Decision-Making with Explainable AI

Frequently Asked Questions

How does HexAgent deal with missing or outdated equipment metadata like design specs or P&IDs?

HexAgent uses inference-based gap filling and historical performance learning to approximate missing parameters, flagging confidence levels so engineers can verify or calibrate later.

What’s the typical deployment time for HexAgent in a refinery preheat system?

A standard deployment takes 4–6 weeks including data integration, knowledge graph setup, agent training, and performance validation, assuming access to necessary instrumentation and records.

Can HexAgent simulate what-if maintenance delays and their impact on heat efficiency?

Yes, it can simulate scenarios such as exchanger fouling progression and its cascading impact on thermal load, energy cost, and downstream unit performance.

How does HexAgent prioritize multiple maintenance recommendations across exchangers?

It uses a risk-based matrix combining thermal degradation rate, equipment criticality, outage impact, and safety history to prioritize shutdown or repair actions.

What’s required to onboard legacy exchangers into the optimization model?

Legacy equipment can be onboarded using design documents, historical data, and minimal tagging, with agents inferring missing context through pattern recognition.

How does HexAgent optimize under variable crude feed conditions?

It uses adaptive models to rebalance exchanger loads dynamically based on crude slate properties, flow rates, and feed temperature variation.

Can HexAgent interface with plant DCS for real-time adjustments?

Yes, it can issue soft recommendations or close-loop control commands through OPC or API bridges based on plant control philosophy.

How are anomalies in heat transfer behavior detected proactively?

Agentic AI continuously compares live performance against expected thermodynamic behavior and flags early deviation before significant energy losses occur.