The Domain-AI Operating System for Industry

AI PlantOps

Unlock interconnected industrial intelligence with AI PlantOps

Why AI PlantOps?

Industries run on complex processes, legacy optimizers, and siloed AI models. Yet, decision-making remains fragmented — plant sections optimize in isolation, operators drown in dashboards, and models often stay unused.

AI PlantOps was built to bridge this gap. It fuses domain intelligence, machine learning, symbolic reasoning, and physics-based validation into one interconnected operating system. The result: a new paradigm of AI PlantOps — where every section, cluster, and workflow is digitally traceable, intelligently optimized, and seamlessly connected.

What is AI PlantOps?

AI PlantOps is the operating fabric of industrial plants. It delivers:

Process Traceability

End-to-end visibility of streams, assets, and quality through a process-aware knowledge graph.

Unified Intelligence

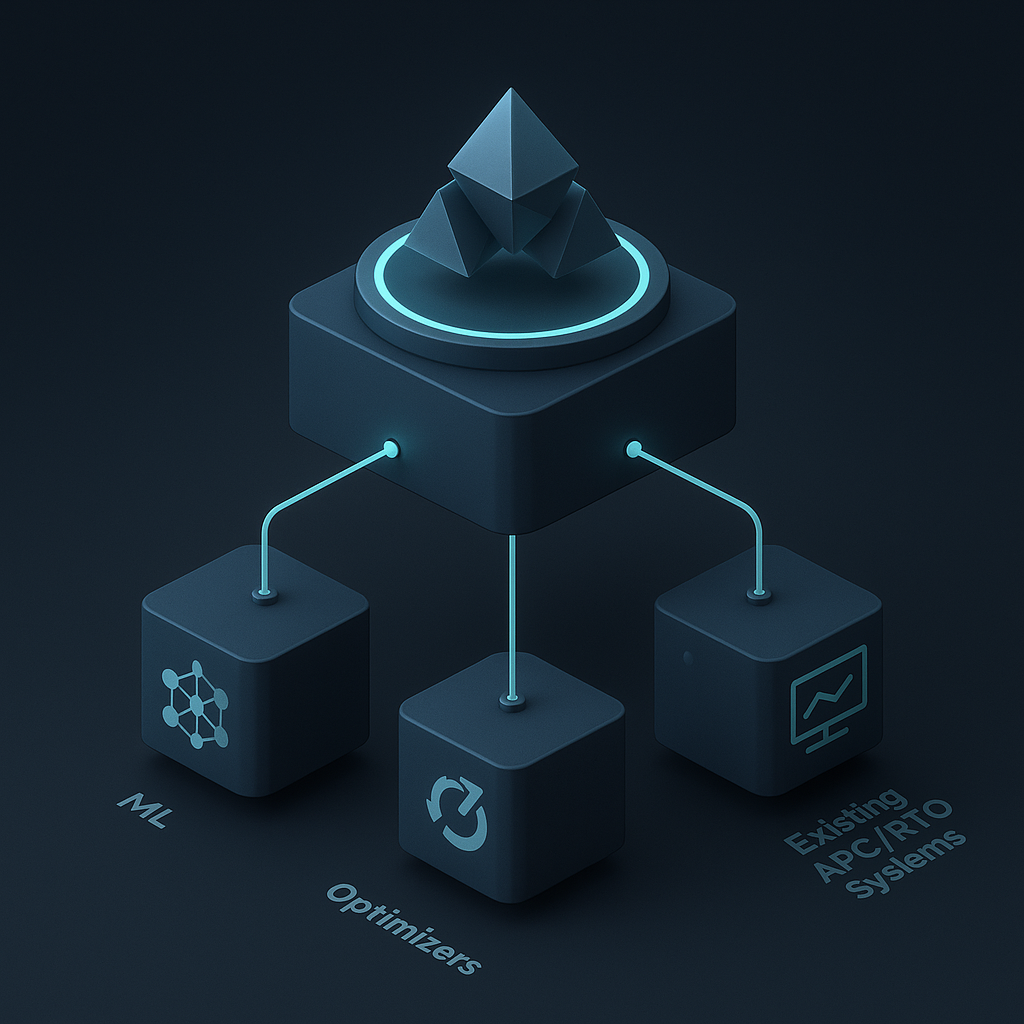

ML models, optimizers, and existing APC/RTO systems connected into a higher-order orchestration layer.

Cognitive Workflows

Context-aware AI and agentic reasoning for dynamic decision support.

Validated Decisions

Backed by a control twin (physics-augmented advisory agent) to ensure feasibility and reliability.

AI PlantOps is not just predictive. It is prescriptive, interconnected, and plant-wide.

How AI PlantOps Works?

Interact with the 3D pyramid to explore how AI PlantOps works from the ground up.Each layer of the pyramid is designed to give you a deeper understanding of the system's structure:

🔹 Rotate, zoom, and click on each layer to view detailed descriptions.

🔹 Visualize how the Foundation, Enablement, and Application layers connect and build on one another.

🔹 Discover how knowledge graphs, AI models, and real-world applications come together in a unified OS.

Dive in and see the architecture come to life in 3D!

Components of AI PlantOps

Process-Aware Knowledge Graph

Digital DNA of the plant for end-to-end traceability, causality, and reasoning.

Machine Learning

Predictive insights on quality, reliability, energy, and production performance.

Context-Aware AI

Cognitive agents that understand plant situations, workflows, and operator intent.

Physics-Augmented Agentic AI

Multi-agent systems that blend first-principles physics with AI reasoning for validated decision-making.

Control Twin (Validation Layer)

A first-principle advisory agent acting as a back-end guardian, validating every AI recommendation before action.

AI PlantOps Philosophy

Plants are not isolated units — they are networks of streams, utilities, and workflows. Optimizing one section without considering its impact on others leads to trade-offs, not transformation.

across symbolic, ML, optimizers, and physics models

Workflow Use Case

Industry Use Case

1. Maintenance & Planning

2. Energy & Utilities

3. Process Optimization

4. Emissions & Compliance

Industries

Upstream operations are marked by subsurface uncertainty, equipment reliability challenges, and rising cost pressures. Xyve OS enables reservoir-to-facility optimization, ESP/PCP pump failure prediction, and production planning that adapts in real time. The result is higher recovery, lower lifting costs, and fewer unplanned shutdowns.

Refineries are complex networks of crude streams, conversion units, hydrogen, and utilities — often optimized in silos. Xyve OS interconnects these clusters, enabling crude-to-product optimization, hydrogen network balancing, and emissions compliance in a single decision fabric. This unlocks margin uplift, energy savings, and reliable compliance with sustainability targets.