Oil & Gas Upstream

Domain-Embedded AI for

Production & End-to-End

Maintenance Repair Operations (MRO)

Built by Engineers | Powered by Physics | Scaled with AI

Tridiagonal.AI (T.AI) is a domain-driven Industrial AI partner focused on upstream oil & gas production optimization and physical asset management.

We combine deep process engineering expertise with state-of-the-art AI technologies to embed operational intelligence directly into production systems — not as dashboards, but as decision systems.

Our Upstream Engineering Foundation

T.AI is the Industrial AI division of the Tridiagonal Group—a global process engineering and optimization organization with over 19 years of experience across oil & gas and complex process industries.

The Group operates an Experimental R&D and Innovation Facility established in 2010 with sponsorship from Chevron Technology Ventures. This lab supports global energy majors in:

- Production Optimization

- Flow Assurance Studies

- Multiphase Systems Modeling

- Process Performance Enhancement

- Asset Reliability Engineering

We have supported global energy operators, including Chevron, BP, Shell, Total, Exxon, PETRONAS, KOC, and others.

Our roots are in physics, thermodynamics, multiphase flow, and optimization—not generic data science.

Production Optimization Intelligence

We engineer AI systems that understand the physical behavior of production systems.

- Well and artificial lift optimization

- Network constraint modeling

- Separator and compression efficiency

- Production deferment risk modeling

- Throughput maximization under integrity constraints

- Energy intensity reduction

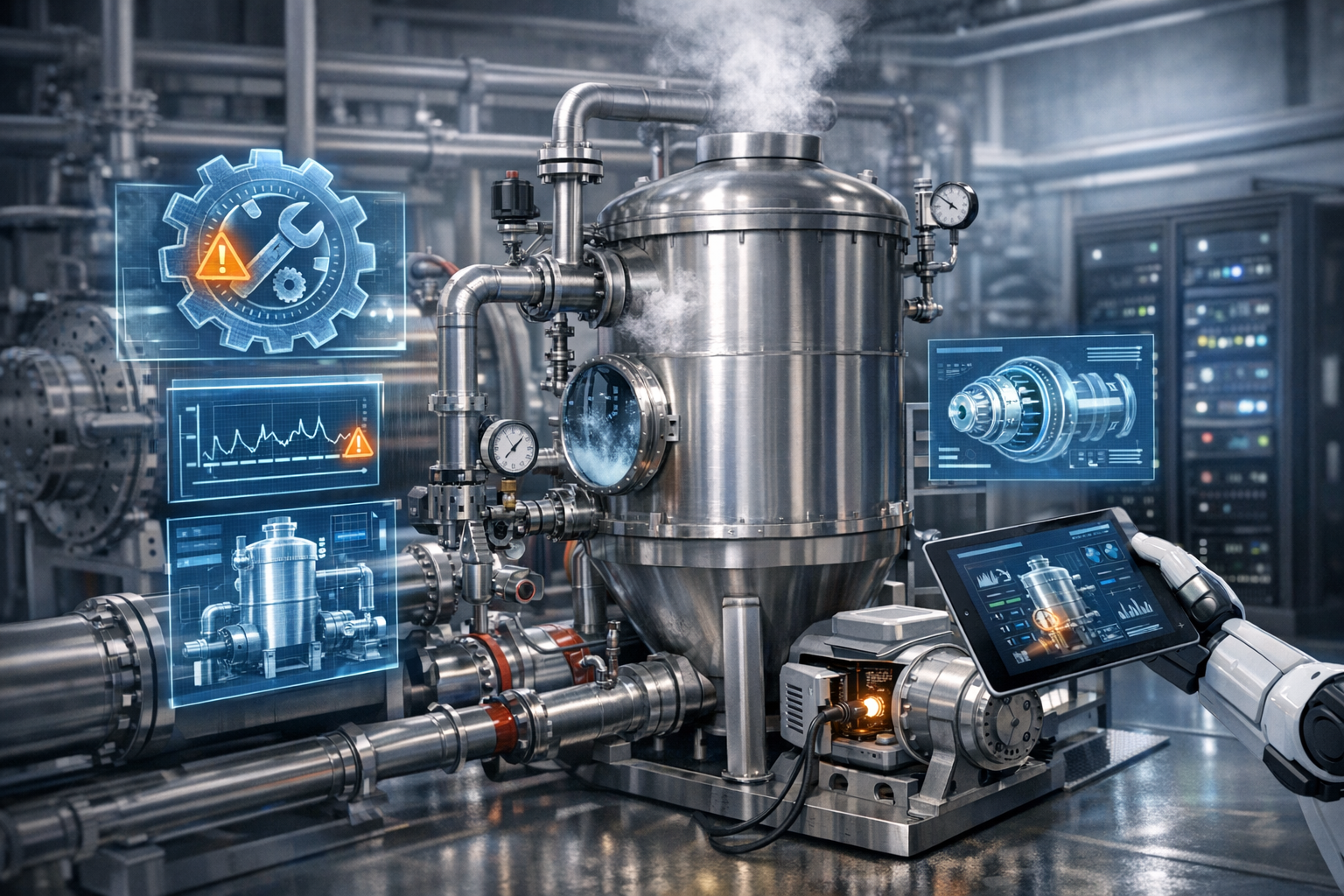

End-to-End Maintenance, Repair & Operations (MRO)

We unify production and reliability into a single intelligence layer.

- Predictive maintenance for rotating & static equipment

- Risk-based asset prioritization

- Failure mode modeling

- Degradation and Remaining Useful Life analytics

- Maintenance strategy optimization

- Spare parts criticality & inventory intelligence

We move beyond condition monitoring to production-aware maintenance decision systems.

Oil & Gas - Resources

Distillation Columns Efficiency

The Golden Batch in distillery manufacturing represents the ideal production outcome.

Heat Exchangers Performance Monitoring

Predicting the end-of-cycle (EOC) for a heat exchanger due to fouling is a persistent challenge for refineries.

Performance Optimization in Process Compressors

Unplanned downtimes lead to reactive and time-based maintenance which can be costly and inefficient.

Virtual Metering for Production Estimation

In the oil and gas industry, production allocation metering is often less accurate than desired, making it challenging to estimate precise production rates

Furnace Efficiency Prediction

Ethylene is produced through a cracking process within furnaces. However, a significant challenge

lies in coking, where undesirable carbon deposits form on the furnace walls during operation.

Our Technology Philosophy

No platform replacement.

No lock-in.

No over-engineered subscription dependency.

Our Technology Philosophy

We Build AI Systems That Are:

- Physics-informed

- Ontology-driven

- Explainable and auditable

- Secure by design

- Vendor-neutral

- Modular and scalable

Our Capabilities Include:

- Machine Learning & Time-Series Analytics

- Hybrid Physics + AI Modeling

- Symbolic AI & Rule-Based Systems

- Multi-objective Optimization

- Agentic AI for Prescriptive Orchestration

- MLOps & DevSecOps Governance

We Integrate Seamlessly With:

- SAP PM/MM

- Historian Systems (PI, IP.21)

- SCADA/DCS

- AWS & Azure

- Hybrid OT/IT Architectures

No platform replacement.

No lock-in.

No over-engineered subscription dependency.

Our Frameworks for Upstream

Our Team

Our team combines:

• PhD-level experts in process systems, multiphase flow, optimization, and applied AI

• Upstream production and reliability engineers with field experience

• AI architects experienced in industrial deployment

• Optimization specialists (LP/NLP, multi-objective systems)

We blend academic rigor, operational realism, and deployment discipline.

Our Differentiation

Unlike large consulting firms:

• We do not sell hours.

• We build operational capability.

Unlike OEM digital solutions:

• We are vendor-neutral.

• We integrate into existing ecosystems.

Unlike generic AI startups:

• Our models are grounded in physics and asset behavior.

We operate as an owner-operator trusted partner, aligned to value creation—not license expansion or headcount scaling.

Our Frameworks for Upstream

We have developed structured frameworks for:

-

Integrated Production Intelligence

-

Asset Reliability & Risk Intelligence

-

Production-to-Maintenance Decision Architecture

-

Intelligent MRO Optimisation

-

ESG-Embedded Operational Optimisation

-

Industrial Ontology Modelling

These frameworks accelerate deployment while maintaining engineering rigor and governance discipline.

Our Commitment

We partner with upstream operators to:

- Increase production efficiency

- Reduce unplanned downtime

- Improve asset reliability.

- Optimize working capital

- Embed intelligent workflows.

- Align operations with ESG objectives.

We focus on measurable outcomes—not consulting slide decks.

We are here to help you

Uncover how our capabilities can propel your organization forward. Provide your focus areas, and we will deliver tailored solutions designed to meet your unique objectives.